Self-assembly connectors target custom cable assembly

Article By : Harting

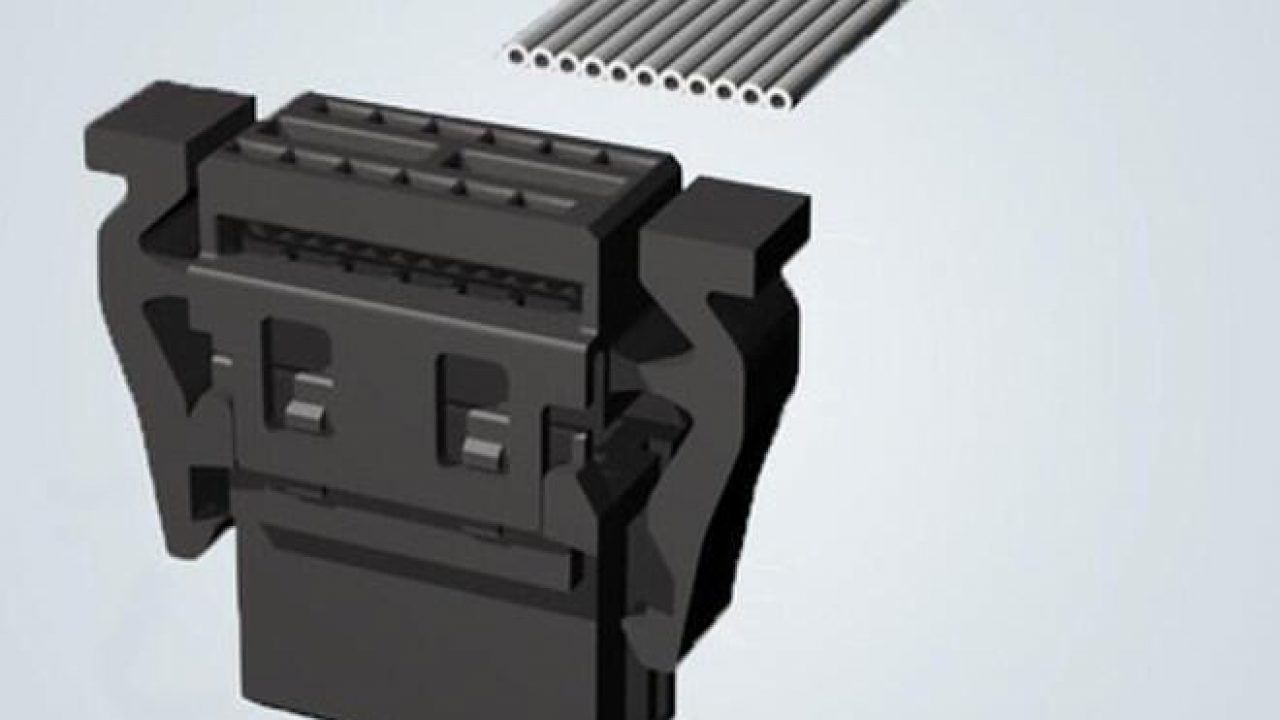

The new 1.27mm pitch connectors are equipped with insulation displacement connection termination technology.

Harting has added individual cable connectors for custom cable assemblies to its har-flex connector line-up.

The new self-assembly connectors offer customers an even higher degree of flexibility and versatility in the connection of PCBs using custom-length cable assemblies, according to the company. The new 1.27mm pitch connectors are equipped with insulation displacement connection (IDC) termination technology, which makes electrical contact via insulation displacement contacts that cut through the jacket of the ribbon cable and establish a secure, gas-tight connection.

Guide grooves incorporated into the insulating moulding allows the ribbon cable to be securely and precisely guided through the cable duct, according to Harting. As a result, the individual stranded wires of the ribbon cable always contact the correct insulation displacement terminal. The connectors are designed for use with 30AWG ribbon cable.

Aside from the connectors, Harting also offers associated assembly tooling using a baseplate designed for use with a conventional hand bench press and flat rock tool. The baseplate ensures reliable cable guidance and support for the connector during the assembly process. This, in turn, produces a reliable electrical connection, while the sensitive insulation displacement terminals are also protected against mechanical damage.

Optional mountable strain-relief components and locking levers protect and secure the mated electrical connection of the cable connector against vibration and other mechanical stresses during operation. This ensures that the high demands of an industrial-strength, miniaturised connection are fully met, according to the company.

Subscribe to Newsletter

Test Qr code text s ss