Rohm system monitors machines for efficiency

Article By : ROHM Semiconductor

The real-time detection and monitoring system helps factories move from preventive to predictive maintenance, saving downtime and costs.

A modular system proposed by Rohm Semiconductor would be able to detect machine failures in advance by integrating pressure, temperature, colour and other sensors that cover mechanical, environmental and optical abnormalities. In addition, sub-GHz technology supports multiple wireless nodes with a range of up to 1km.

Preventive to predictive maintenance

In industrial applications, it is often important to monitor the status of machines in real-time to provide early detection of machine failure. A single malfunction of factory equipment can result in substantial losses, leading manufacturers to consider machine health monitoring systems that prevent failure by monitoring equipment and conditions within factories.

Machine health monitoring, which is a type of visualisation method for factories, is designed to transition from preventive maintenance to predictive maintenance by continuously collecting and analysing information on the condition of equipment and facilities within factories.

The proposed system enables continuous monitoring of all equipment for mechanical, environmental and optical anomalies that can indicate potential malfunctions and/or stoppages before they occur by allowing users to quickly install temperature, colour, barometric pressure and other sensors on to existing solutions.

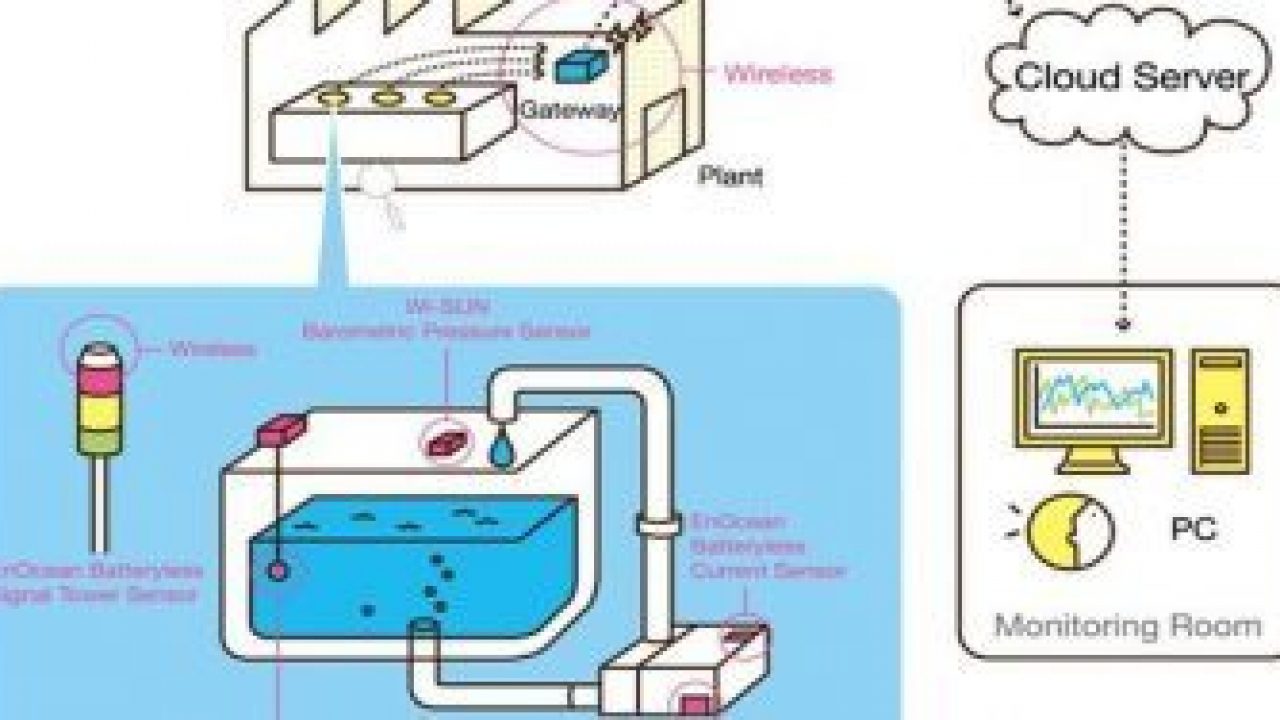

Figure 1: A working demo setup of Rohm's system simulates a typical pump used in factories, circulating a tank filled with liquid.

Key features:

- Allows access to plant information anytime, anywhere

- Monitoring the health of the plant

- Enables preventive and predictive maintenance

- Allows for the management of defective products

In the demo above, 11 sensor nodes are attached to the pump and tank, and data acquired from each node is wirelessly transmitted to a control device. When the control device detects an abnormality in the data, it can immediately issue an alert and/or stop operation. Transmitting the data to a cloud server via a gateway also makes remote monitoring possible from virtually anywhere in the world.

Subscribe to Newsletter

Test Qr code text s ss