Molex’s silver flex circuits cut down expenses

Article By : Graham Prophet

Molex has developed a method using silver ink to screen traces on PET in a variety of applications, an alternative to pricey copper circuits.

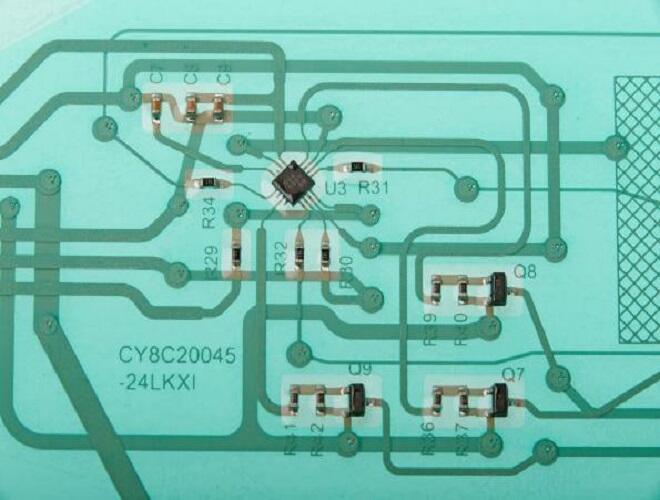

Molex has developed a silver ink technology that prints silver flexible circuits on polyester substrates with traces and down to 0.13mm spacing.

The method may be a cost-effective process compared to traditional flexible circuits of etched copper traces on polyimide and PCBs, according to Molex. With this method, there are reduced restrictions on attaching fine-pitch, IC-based components on PET, and a system that is compatible with standard SMT processes.

“Designers must fit ever-smaller components and traces on limited real estate,” said Dan Dawiedczyk, director of marketing, Molex. “Polyimide can accommodate that need, but is more expensive than PET. As an alternative to copper circuits, Molex has the option to use new silver ink technology and advanced printing to screen extremely fine traces on PET in a wide variety of applications.”

Dawiedczyk noted that in addition to reducing costs by applying silver traces to PET, those traces are inherently less expensive than copper etching and associated processing. Additionally, the manufacturing of the Silver Flexible Circuits does not require harsh chemicals or a waste treatment facility.

The technology allows the attachment of 0.50mm IC-based components on PET via a bonding process using traditional SMT equipment. That process also enables attachment of right angle LEDs, enabling enhanced backlighting for user-interface applications. In the final step of the attachment process, a UV-cured encapsulant is used to protect the solder joints, making it possible for them to withstand vibration and mechanical shock.

First published on EDN Europe

Subscribe to Newsletter

Test Qr code text s ss