A Week in European Automotive: Startups Reinventing the Car

Article By : Nitin Dahad

European auto startups are putting a complete car platform in a wheel and solving last mile delivery with autonomous vehicle.

“We’re disrupting the automotive industry!" That’s a common claim from many briefings we get from emerging startups. Last week was not unusual — one told us how they’ve solved the challenge of producing roadworthy autonomous delivery vehicles for last mile delivery; another has ‘reimagined’ the vehicle by integrating all the components found under the hood of a car into the wheel.

Both are at early stages; both claim investment interest from retailers and Tier 1s in the automotive manufacturing supply chain.

A Modular EV Platform, All Built into The Wheel

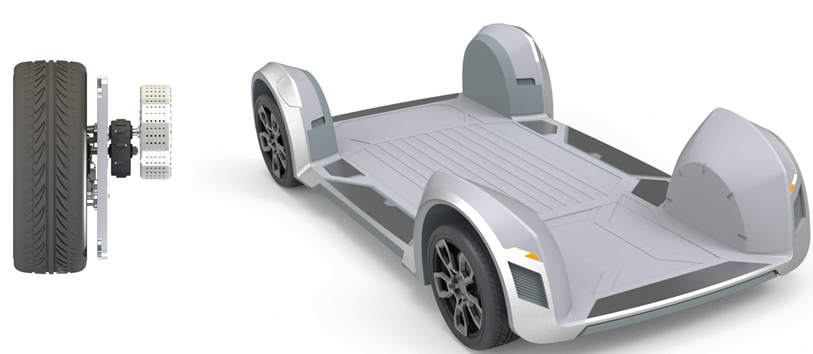

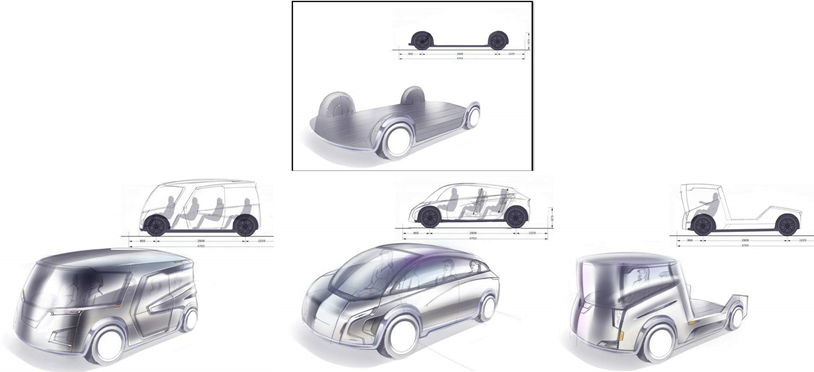

Israeli startup REE, which came out of stealth mode today, has a flat and modular platform that fundamentally changes the way electric vehicles (EVs) will be built. The company integrates all of the components formerly found under the hood into the wheel. It says it offers optimal freedom of design, and the potential for multiple body configurations on a single platform.

Putting the motor, steering, suspension, drivetrain, sensing, brakes, thermal systems and electronics in the wheel leaves a ‘flat’ platform. This provides a low center of gravity to maximize efficiency and supports the vehicle’s agility and stability. The design also drastically reduces its footprint, weight, and improves both energy-efficiency and performance — aspects crucial for electric and autonomous vehicle development.

In an interview with EE Times, Daniel Barel, co-founder and CEO of REE, told us, “The industry is still using 80-year old concepts for car design, even though the technology has changed. There have been many advances, but these have still only been incremental, and it doesn’t make sense to build EVs based on these old concepts.”

He said they wondered, “What if we could build a rolling chassis platform that is modular and would still be appropriate even one hundred years from now?” He added that the single biggest expenditures for an OEM was the platform, which can cost billions of dollars, which is why they started developing a platform that could support any shape and size of car.

REE’s platform provides automakers, mobility providers and delivery companies a tailor-made solution. Based on a novel quad-motor system, and including active height-levelling suspension, steer-by-wire and a smart quad-gear box, the technology provides the basis of any type of vehicle from a high performance car able to do 0-60 mph in less than 3 seconds to an off-road SUV with advanced active suspension technology. The platform can also be used as the base of a robotaxi or even a 10-ton cross country truck.

By adopting a universal framework, this can replace the multiple platforms that OEMs develop, resulting in substantial savings. The design and validation of each platform traditionally costs manufacturers $20 billion. By enabling them to utilize one platform for all of their vehicles, costs could be slashed, while performance, safety, comfort and energy efficiency can all be matched or improved.

Barel said they’ve been validating the technology for the last six years in stealth. In early 2018, they established some initial discussions with a Tier 1 and an OEM to gauge interest. “They loved our idea and became investors and also wanted us to expedite what we were doing.” Since then, REE has been building its network and establishing relationships with players such as Mitsubishi, NSK, Tenneco and FCA. The company is essentially the system integrator, developing both the hardware, including electronics, and software, selling its wheel to the tier one manufacturers and OEMs.

Although Barel wasn’t prepared to disclose funding to date, he said it’s sub-$100 million. The company employs around 100 people, 50 of whom are based in Israel. He added that the full solution will be presented with its partners later this year and manufactured globally. Barel is also co-founder of SoftWheel, a developer of in-wheel suspension technology for personal mobility, which has raised $40 million to date and announced investment from Mitsubishi Corp. last year.

‘First’ Roadworthy Last Mile Autonomous Delivery Vehicle

Meanwhile, at the Goodwood Festival of Speed last week, the UK’s Academy of Robotics unveiled what it claims is Europe’s first road-worthy autonomous delivery vehicle focused on tackling the last mile delivery challenge.

A project that started two years ago by a group of computer scientists and academics now expects to have a car on the road within 90 days and interest from a major Chinese retailer (we are told it is not Alibaba).

The vehicle, called Kar-go, features artificial intelligence (AI)-based navigational capabilities. These include a machine-vision system designed by members of the team who worked on the Mars rover, and a patented internal package-sorting mechanism to shuffle parcels into the correct order for drop-off. These technologies are combined with an Nvidia Drive supercomputer and a Tesla battery to create a fully operational and scalable solution for last-mile delivery.

Its modular driverless delivery technology combines continuous-time recurrent neural networks (CTRNNs) with CNNs (convolutional neural networks) and long short-term memory (LSTM) to create a top-level controller system which can ‘learn’ from the past, ‘perceive’ its environment and make any necessary corrections. This complex hierarchical system can run on a single NVIDIA GPU-equipped desktop.

Kar-go claims its combination of navigational freespace and pilotnet decision-making software enables the vehicle to navigate safely, even without GPS, in complex situations such as roundabouts and junctions.

The vehicle was designed in collaboration with the UK’s driver and vehicle licensing agency (DVLA) to operate safely even on unmarked roads. It uses a terrain-training approach to become an expert in its particular route so it can then focus on any abnormalities in that route. The vehicles will operate in fleets, each one delivering within a dedicated local area, so it never needs to drive too far in an untested environment.

By automating the last stage of delivery, from local depot to customer, the company expects to substantially reduce costs. As an electric vehicle, capable of delivery 24/7, the goal with Kar-go is to provide an efficient and sustainable logistics solution to serve growing delivery demands from online retail.

Founder and CEO, William Sachiti, emphasized to EE Times that this is not a concept car. The first trial is expected in Surrey within 90 days, once they get the vehicle registration. Sachiti said they’ve had significant interest from retailers and large logistics firms — including a Chinese retailer which doubled its offer for both investment and operational support when it saw the vehicle at the festival last week. “We have a waiting list of retailers wanting to consider Kar-go, but we’re deciding on our go-to-market plan still and what is the best route forward.”

Sachiti said the company already has commitments of signed paid-for trials, but it's still considering what the actual business model should be. The cost of the vehicle is around £40,000-£50,000 (US $50,000 – $62,000). The company is evaluating a model in which the retailer pays towards the cost of the vehicle and then a unit cost for each delivery. But it could just as well be on a lease basis, or some other model they haven’t considered yet.

Kar-go is manufactured in Brighton in the UK in partnership with classic car experts, Pilgrim Motorsport. The chief designer, Paul Burgess, is a former McLaren F1 designer, who worked on the hybrid P1 supercar and the record-breaking, Lemans winning F1 roadcar.

The Academy of Robotics, founded in 2017 in Aberystwyth, Wales, is a technology company with a technical team of engineers, scientists, and researchers. It specializes in creating technology to perform or simplify complex tasks. Combining the best techniques from machine learning and mechatronics the academy builds powerful self-adapting machines and task-specific artificially intelligent software. The university where it is based was the home of the team who developed the intelligent vision system for the autonomous Mars rover and it was here that founder Sachiti met Dr. Elio Tuci, as well as lead engineer Dr Aparajit Naraya.

Lead scientist Tuci is one of Britain’s leading authorities in the field of automation and autonomous machines, currently leading research at department of computer science at Middlesex University, and co-author of more than 70 peer-reviewed scientific publications. Lead engineer Naraya leads the driverless architecture of the system, with a PhD in artificial intelligence for driverless systems and four years working on new ways for driverless cars to operate on unmarked roads.

Subscribe to Newsletter

Test Qr code text s ss