STT Increases MRAM Spin-Torque Efficiency

Article By : Gary Hilson

Data retention capabilities higher, power draw lower, as Spin Transfer Technologies hones its tech

TORONTO — One the primary players in the emerging MRAM market has developed proprietary technology it says will enhance the performance of any MRAM array by increasing the retention while simultaneously reducing current.

Announced at Intermag, a conference on applied magnetism, Spin Transfer Technologies (STT)’s Precessional Spin Current (PSC) structure has the potential to enhance MRAM’s density and zero leakage capabilities, according to Mustafa Pinarbasi, the company’s chief technology officer. In a telephone interview with EE Times, Pinarbasi said the structure could be applied in mobile, datacenter CPUs and storage, automotive, the Internet of Things and (IoT) and artificial intelligence, among others.

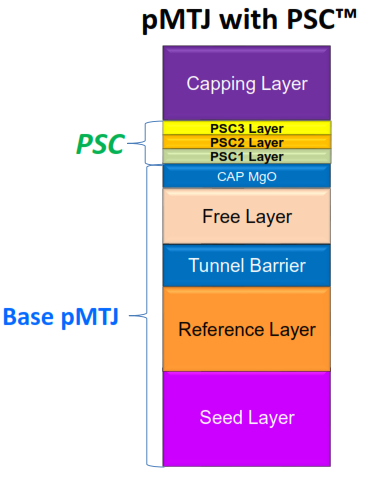

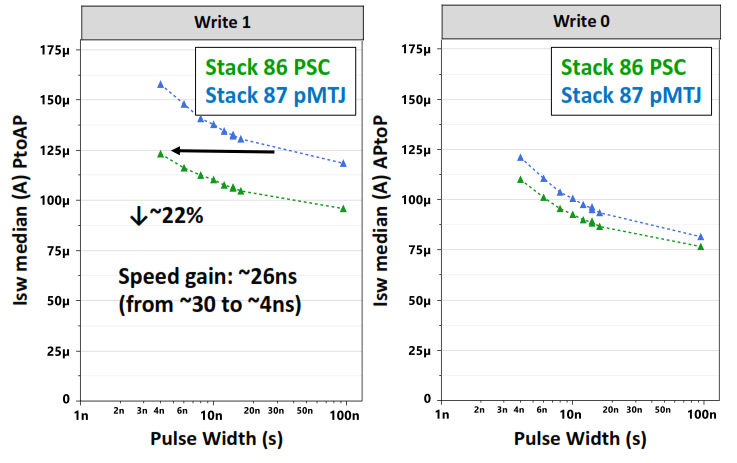

Pinarbasi said the PSC structure will increase the spin-torque efficiency of any MRAM device by 40 to 70 percent. This means not only are its data retention capabilities are much higher, but it will consume less power. Pinarbasi said the gain translates into retention times lengthening by a factor of more than 10,000 — so one hour becomes more than one year — but the write current is reduced. In addition, the PSC gets even more efficient as the perpendicular magnetic tunnel junction (pMTJ) gets smaller. “The structure that we have developed is a modular structure, and it really is an extension of the PMTJ device,” Pinarbasi said.

”We designed this from the get go to be a modular approach,” added Jeff Lewis, STT’s senior vice president of business development. “That means we can add the PSC to anybody else’s pMTJ. You can think of it as a turbo charger for existing MRAM implementations.”

The PSC structure is designed to be incorporated into any MRAM manufacturer’s existing process, Lewis said. There’s no additional materials or tools than those already used in the production of STT-MRAM, so the structure adds virtually no complexity or cost for the foundries.

There are two specific effects at work in the PSC structure, Pinarbasi said. One is static and the other is dynamic. “Static effect is the one that enhances the retention of the device by a significant amount,” he said.

The dynamic effect has the switching from zero to one or vice versa, and that is important because there is always a correlation between static retention and the current, said Pinarbasi. “We have separated those two effects. We can independently enhance retention, and at the same time lower the current,” he said.

Although the PSC structure enables STT-MRAM to address the size and cost drawbacks of SRAM, as well as the volatility and power complications of DRAM, STT doesn’t just see PSC-enabled MRAM as replacement for existing memory technologies, but also be used in greenfield opportunities presented by IoT, automotive and AI, said Pinarbasi.

Thomas Coughlin, a veteran analyst and founder of Coughlin Associates, expects that in general there will be native markets that will develop for MRAM, particularly embedded applications, and it’s already replacing what could have been SRAM or different memory caches inside the device. “There’s going to be some market share changes, but also new market development because of these devices and their non-volatile memory capabilities,” Coughlin said.

While MRAM has established itself as playing an important role in the future of memory devices, he said, it’s still early days and MRAM is still mostly being used in niche applications. Time will tell how much impact Spin Transfer’s PSC structure will have. “There definitely would be value making a more compact structure that could be scaled even further than conventional MRAM products,” Coughlin said. “You have to shake things out and see how it works in practice.”

Coughlin anticipates that next year there will be a lot of MRAM products available, especially as the foundries and major semiconductor companies are ramping up, with a big focus on the embedded market. “People will be looking for differentiation, so that may get them to look for ways in which they can lighten technologies that they can put in these products to differentiate themselves from other people’s products,” Coughlin said. “There’s some potentially near-term opportunities in that kind of environment.”

Looking five years out, Coughlin said MRAM will be a larger niche market. “A lot of the commercial products aren’t even going to be out there or in use for another year or two, where they aren’t already,” he said.

—Gary Hilson is a general contributing editor with a focus on memory and flash technologies for EE Times.

Subscribe to Newsletter

Test Qr code text s ss