Safe and secure wireless power solutions

Article By : Ralf Ködel and Ken Moore

Complete wireless charging solutions for cordless user experiences for consumer, industrial, and automotive markets without compromising on high performance and reliability.

The various benefits of wireless charging like convenience, integration with multiple devices, mobility and flexibility drive the market (figure 1). Based on this the overall wireless charging market is growing at a rapid pace. It is expected to have a CAGR about 30 percent during the period 2019 – 2025, reaching 27 billion USD in 2025. Infineon, partnering with Spark Connected, offers complete solutions for wireless charging with dedicated wireless power controller incl. software IP, MOSFETs, drivers, security ICs and application optimized reference designs.

There are a number of challenges for designers of wireless charging products, requiring a deep level of system knowledge and expertise. In addition to issues associated with the charging coils and their interaction with surrounding structures, designers must address efficiency, mechanical packaging and electromagnetic interference (EMI). However, with optimized components and sufficient attention to alignment of charger and device, size of coils and distance between coils, then a good coupling factor can be achieved, and power can be transferred with high efficiency. In addition, metallic foreign objects (such as coins and keys) can be a safety hazard during charging and must be reliably detected through a process called Foreign Object Detection (FOD).

How wireless charging works

Wireless charging uses a changing magnetic field to transfer energy between two objects via coils. The effectiveness of the energy transfer between coils is referred to as “coupling”, and depends on multiple parameters, including coil mechanical design, spacing and alignment. When the coils are aligned and in close proximity, wireless power transmission is nearly as efficient as wired charging.

Wireless charging solutions have two key elements; the transmitter and the receiver. The transmitter contains a MOSFET-based inverter to convert the DC power into an AC waveform to drive the coil and create the alternating magnetic field. In order to provide the flexibility and functionality required, the inverter is controlled by a wireless power controller in real time through the associated MOSFET driver components. The receiver contains a rectifier to convert the incoming AC waveform into DC power and a regulation stage to provide a conditioned supply to the load. Most receivers also contain a wireless power controller which is responsible for overall system management and communication.

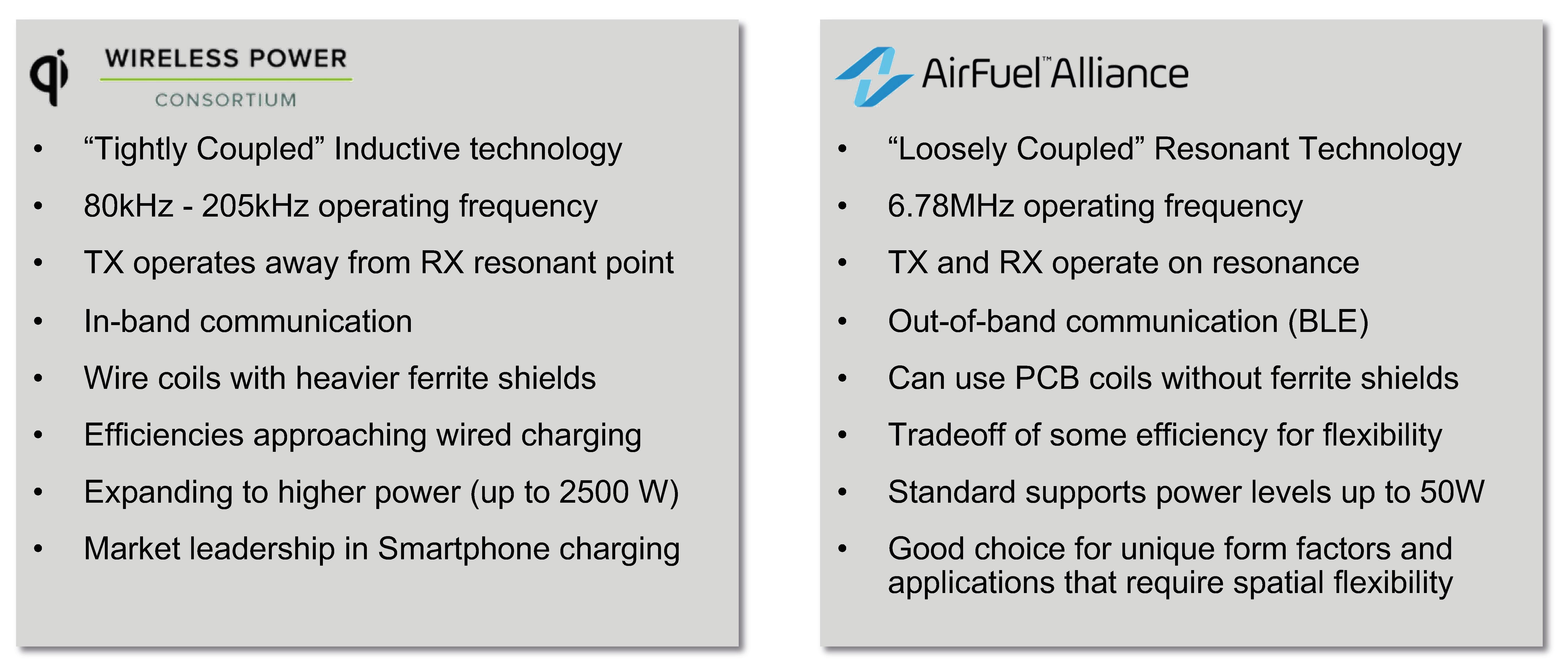

Two types of technology are commonly used to transfer power wirelessly through alternating magnetic fields – inductive and resonant. Reflecting the different benefits of these two technologies, there are two standards bodies active in the wireless charging market: the Wireless Power Consortium (WPC) and the AirFuel Alliance. The main differences between the two standards are shown in figure 2 at a glance.

The Wireless Power Consortium (WPC) supports the Qi standard for wireless charging, which is the leading standard in the market. Qi uses inductive technology that supports efficient and tightly coupled charging. In addition, the upcoming version of the WPC Qi standard contains provisions that create a certified authentication standard. OPTIGA Trust Qi is Infineon's turnkey IoT security solution, designed to meet the challenges of secured wireless charging required by the Qi standard.

The single coil inductive approach is the most prevalent solution on the market and consists of a single transmitter coil operating between 80 – 205kHz. This approach requires centering the device to be charged in relation to the transmitter coil and is only able to charge a single receiver device at a time. With good design and high-quality power conversion electronics the efficiency of this type of charging can match wired charging. Extending this approach to a charger with a multi-coil array brings an additional benefit. The positioning of the device is much less precise and smart systems can detect which coil is closest to the device being charged and direct the power accordingly.

The AirFuel Alliance (AirFuel) has a broad technology platform encompassing resonant and uncoupled technologies. With resonant chargers, the 6.78MHz frequency of magnetic resonance can achieve a much larger vertical range of 50mm or more. Multiple devices can be charged using a single larger transmitter coil, which also provides a larger active charging area or “sweet spot”. AirFuel's resonant technology allows for a more flexible near-field charging experience and offers more positioning freedom over inductive solutions. This technology is suitable for devices that have high metallic content, have compound shapes (unlike a smartphone), or can benefit from multi-device charging.

But there are some challenges with resonant charging. The power has to be switched very fast. This means that the MOSFET’s gate characteristics have to fit in the 150ns cycle requirement. On the other hand, minimum parasitic capacitances have to be reached, while efficient voltage conditioning to control the output power is needed.

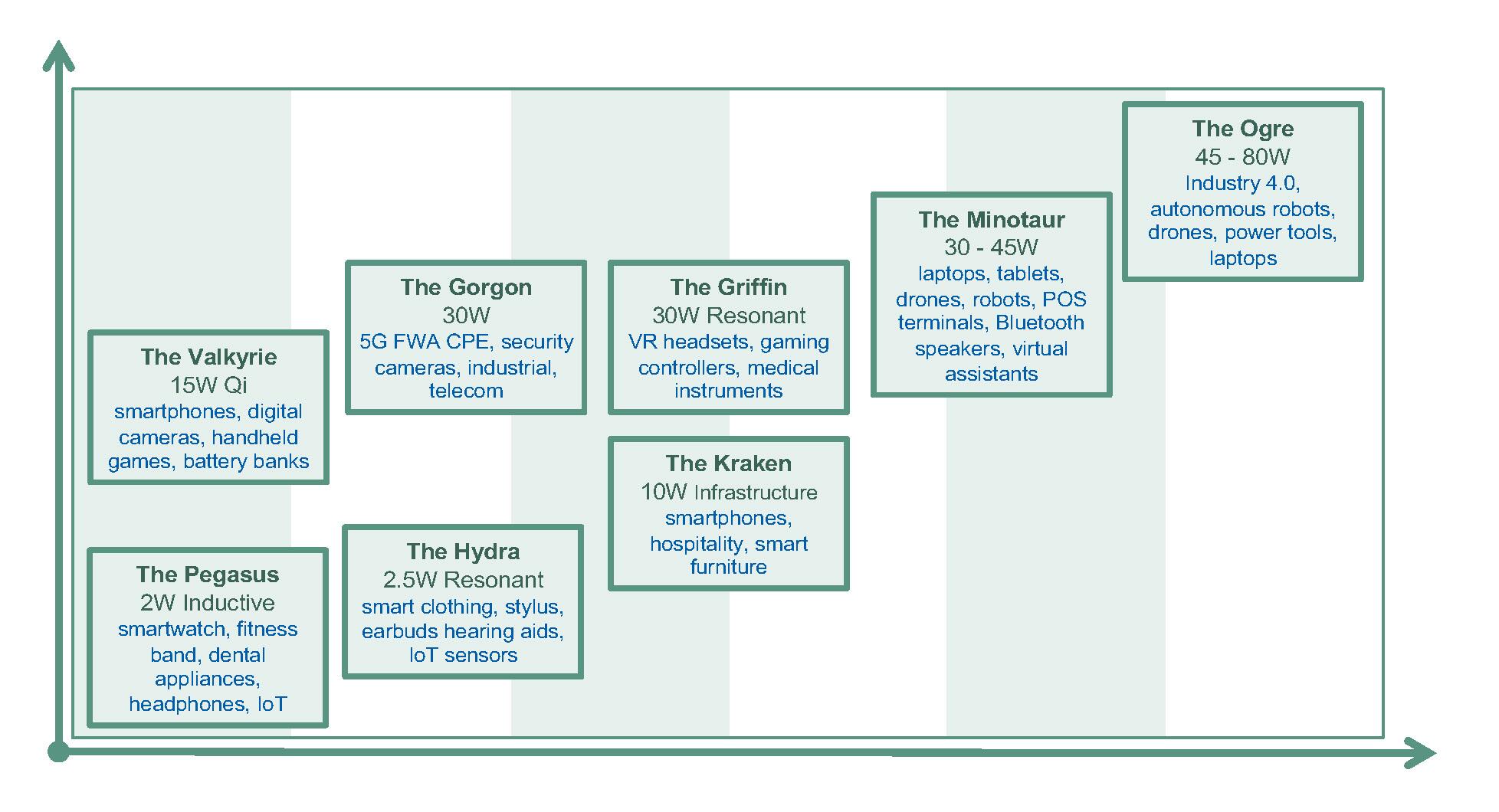

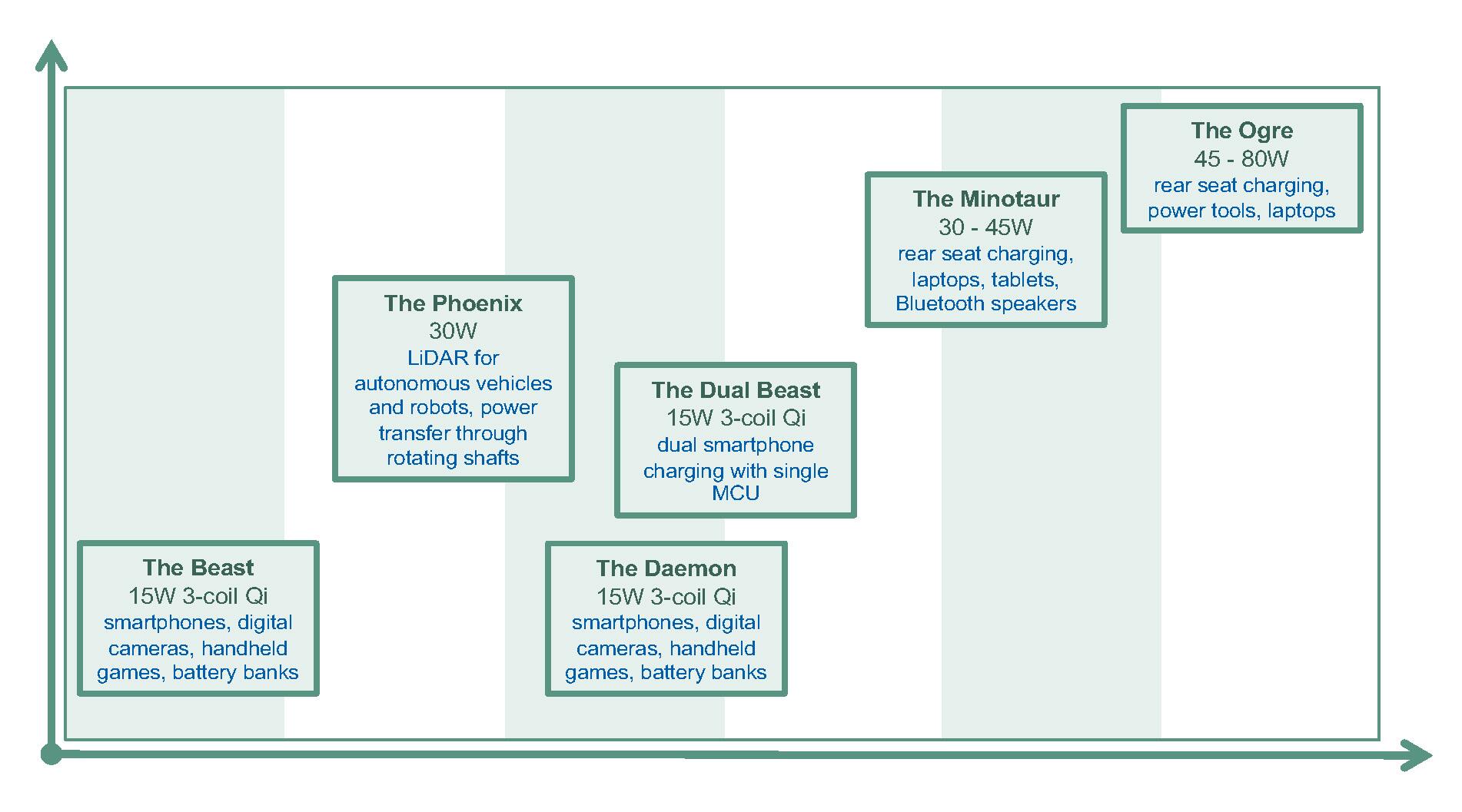

Infineon, through the partnership with Spark, is the only company that offers both inductive and resonant technologies, allowing a custom-tailored solution that uniquely meets all application’s requirements (figure 3a and 3b). Both inductive and resonant solutions can conform to a standard or be proprietary to the application, depending on the market needs.

Robust and reliable FOD

Standard Foreign Object Detection (FOD) methods rely on the large primary coil winding for detecting foreign objects, which reduces sensitivity and signal to noise ratio. Smaller objects are difficult to detect, due to the small impact on the magnetic field of the much larger primary coil. Existing transmitter solutions measure the parameters needed for the power loss calculation (voltage and current) at the DC supply of the inverter. This distorts the measurement when compared with the actual values at the coil, causing an inaccurate transmitter loss calculation.

The Infineon/Spark solution is Qi certified and fully meets Qi FOD functionality and performance. The solution employs more accurate measurement techniques, which improve the performance of the standard Qi FOD method: actual voltage and current are used in the calculation and not the inverter DC power. The solution is more accurate and can detect smaller foreign objects. It prevents overestimation of losses (Foreign Object not detected), or underestimation of losses (FOD fail with no object present). The transmitter employs AI and machine learning to determine if the charging environment is safe when metallic objects are present.

Flexible software-based architecture

Rather than rely on an application specific IC for protocol and power delivery, the strength of the Infineon/Spark wireless charging solution lies in its modular software-based architecture. Wireless power is continually evolving, as standards mature, and new products and applications are introduced to the market. The high software content of the solution allows a common hardware architecture to be used across several reference designs, with each reference design flexible enough to support several types of applications. In addition, future changes to the wireless charging standards can be supported by a software upgrade.

Dedicated wireless power controller based on AURIX and XMC

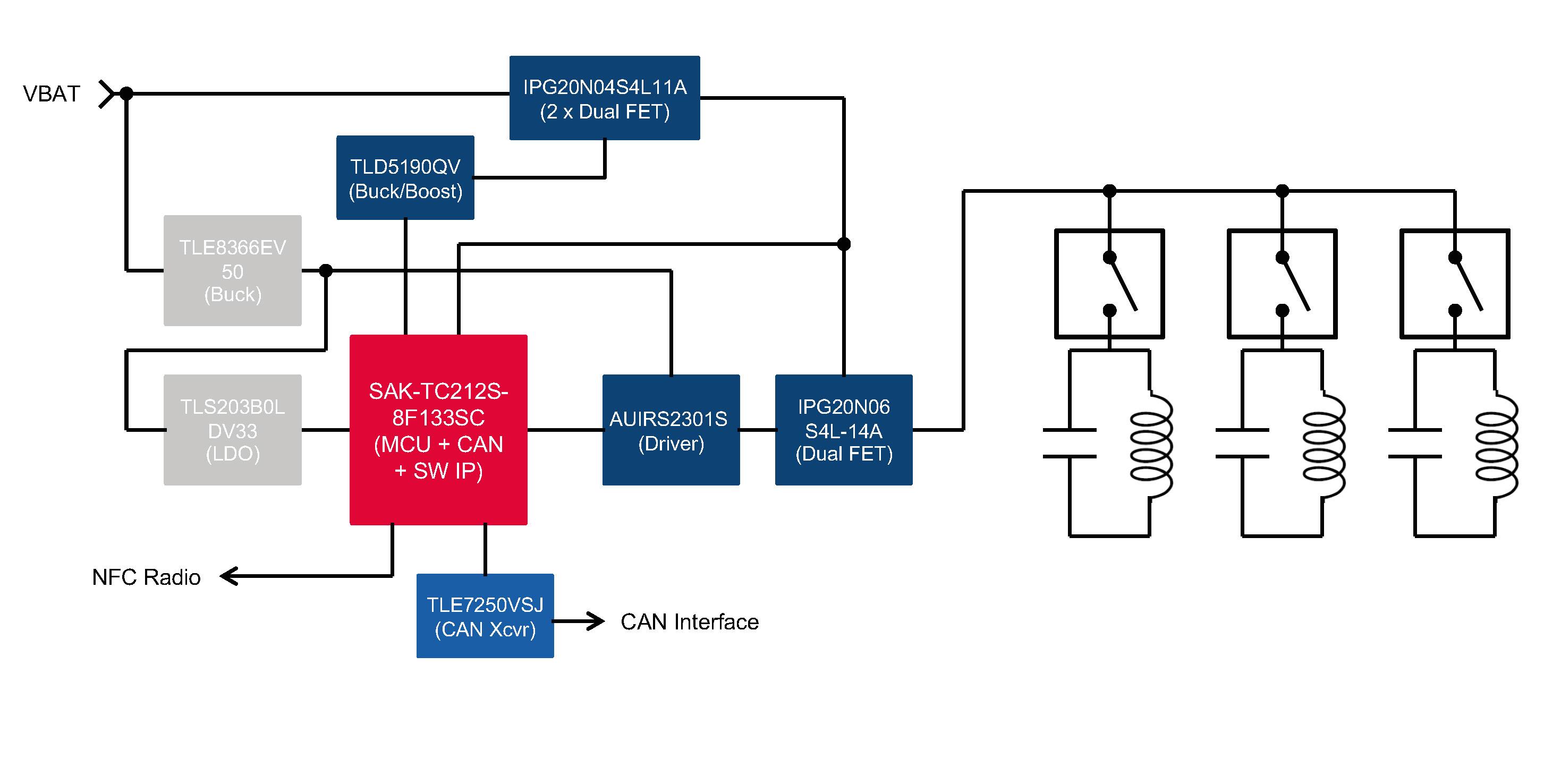

There are dedicated wireless power controllers for wireless charging based on AURIX and XMC families. The AURIX wireless power ASIC like the SAK-TC212S-8F133SC help the next-generation in-cabin wireless charging systems meet strict automotive safety, security, environmental and regulatory requirements, while still enabling industry-leading charging performance and efficiency. This controller works seamlessly with Infineon’s power and interface devices to provide a complete charging solution for smartphones and other connected devices. The controller supports 15W charging for today’s standard Qi and fast charge smartphones and supports future standards with a software update. Other key features of the solution are: Special power drive stage with improved EMI performance of 10 – 15dB over existing solutions; flexible FOD with improved accuracy that can detect smaller objects; support of custom coils and multi-coils; charging two devices using a single controller; full power charging with a 6 – 19V input supply; and built-in security functionality meeting latest automotive requirements.

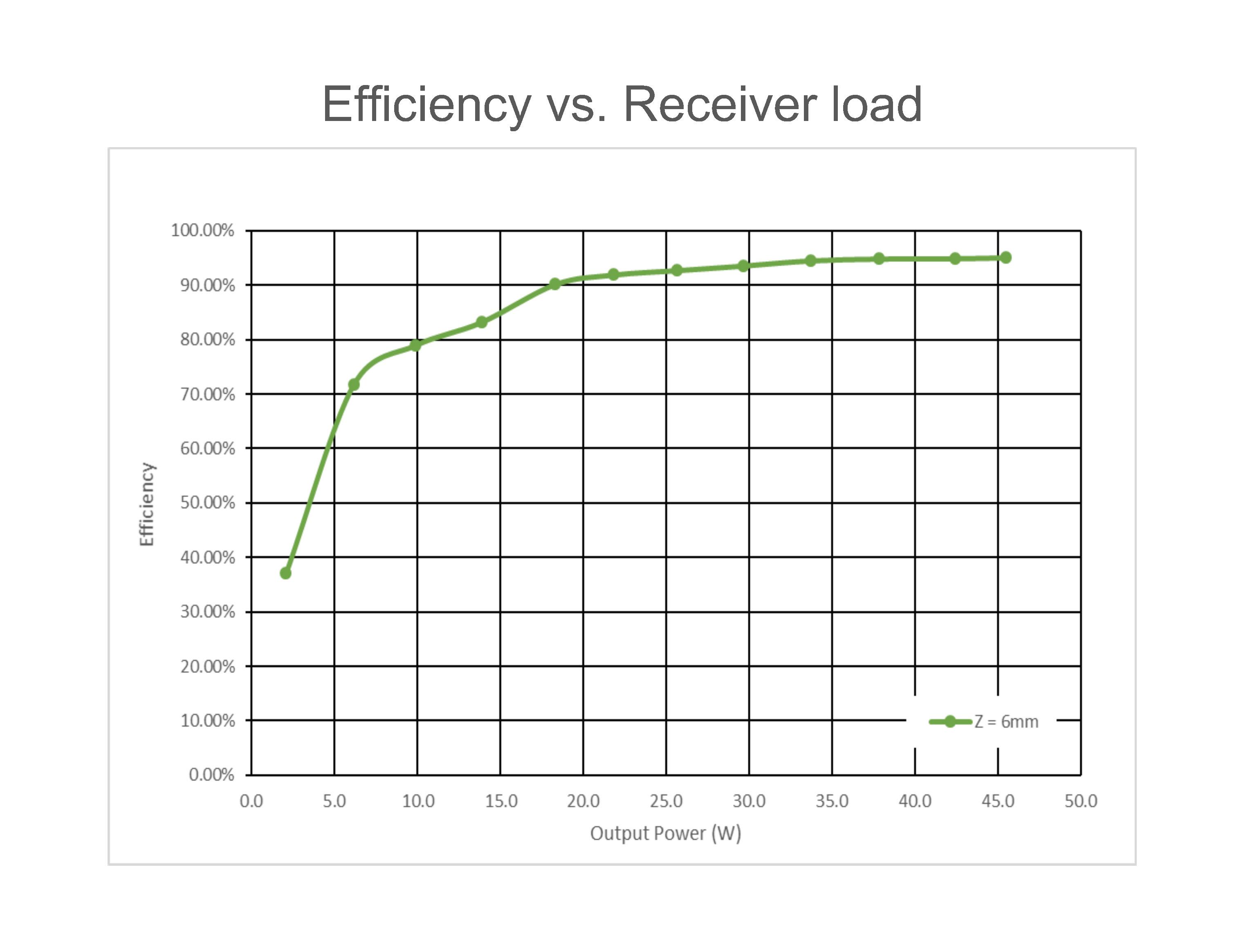

The wireless power controller XMC6521SC-Q040X and the other members of this series based on the ARM® Cortex®-M0 core work seamlessly with Infineon’s power devices in a scalable and cost-effective architecture to provide a complete charging solution for everything from a fast charge smartphone, to a 45W laptop computer, to a 80W drone and beyond. Other key features are the support of existing standards and fast-charge devices; full power charging without exotic thermal management; high efficiency charging rates equivalent to wired charging; support of custom charging profiles and industry standards on the same hardware; flexible FOD with improved accuracy; and support of custom coils and multi-coil architectures.

Reference designs for next generation applications

Working with Spark Connected Infineon provides complete reference design roadmap for both inductive and resonant wireless power solutions (see figure 2) that support many of the current and next-generation wireless power applications: for on-the-go charging, whether in the car, at home or in public places. These reference designs include the hardware design, bill of materials, example PCB layout and all the documentation and support required to integrate wireless charging into the customer’s product.

“The Pegasus” is a low-power inductive transmitter and receiver solution that supports single device charging up to 2W with an input power supply of 5V. Main applications are low-powered products such as wearables, toothbrushes, headphones, hearing aids, smart glasses, smartwatches, fitness bands, smart clothing, smart sports equipment, smart stylus, and IoT.

An XMC based 2.5W low-power solution, called “The Hydra”, is the industry's lowest cost resonant wireless charger. By using a frequency of 6.78MHz, very small coils can be employed in a variety of form factors, with no regard to nearby metallic objects. These benefits make the technology ideal for charging wearables, headphones, smart clothing and other connected IoT applications. The transmitter and receiver solution use resonant technology and supports one-to-one and multi-device charging. The input power supply is 5V – 19V.

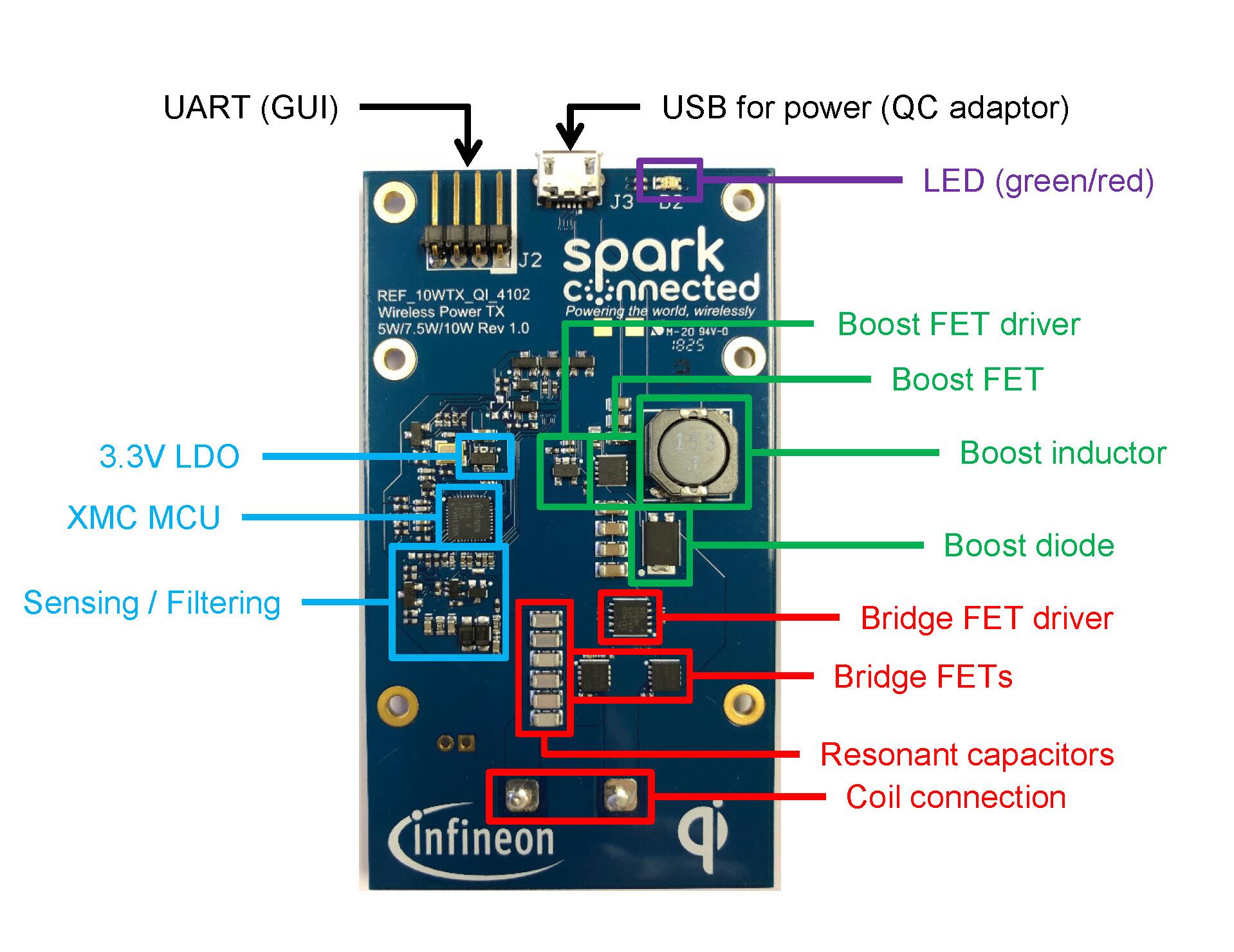

“The Valkyrie” is a certified Qi transmitter that supports the latest 15W power transfer specification for all fast charge smart phones. The solution provides an easy-to-use wireless power design kit and enables high efficiency (>80% tested) combined with class leading FOD. In addition, the solution’s low component count enables designs with reduced system costs (figure 4). It achieves charging rates nearly equivalent to wired charging and supports custom charging profiles and industry standards on the same hardware.

Infineon also provides a 15W 3-coil reference design for automotive in-cabin wireless charging (figure 5), called “The Beast”, which is both Qi certified and automotive qualified. In an industry first, the reference design has also been certified CISPR-25 Class 4, for EMI performance unmatched in the market. The AURIX-based design supports wireless charging, CAN and external NFC-interface with a single CPU. Built-in security functionality (HSM) meets latest automotive requirements. The solution is highly scalable and flexible and provides a very robust FOD. The AURIX can also support the charging of two devices using a single controller, thereby reducing system cost and size.

For applications such as 5G Customer Premises Equipment (CPE), outdoor security cameras, telecom infrastructure and factory automation, a solution called “The Gorgon” provides high efficiency wireless power transmission. A proprietary inductive transmitter and receiver solution, the system can continuously power a device up to 30W through 30mm of glass (including low-E coated glass) or other non-metallic building material.

“The Minotaur” is the only 45W complete wireless charging system for next-generation tablets and laptop computers. The solution provides high efficiency (95% tested) charging that is easy to integrate with a reduced thermal impact (figure 6). The solution extends the existing smartphone charging ecosystem, allowing true backward and forward interoperability for users to take advantage of the growing Qi infrastructure. Infineon and Spark Connected are driving this next generation wireless charging standard with key OEM market makers in this space as part of the Wireless Power Consortium.

At 80W, “The Ogre” is a high-power inductive wireless charging solution that provides high efficiency charging on compact coils without special thermal management. Typical applications are power tools, robots, small appliances, drones, handheld terminals, medical instruments and industrial automation.

Further reference designs will be available on demand. Further Information on Infineon wireless charging solutions is available at www.infineon.com/wirelesscharging. To learn more about how Spark Connected is transforming wireless power delivery with innovative platforms and disruptive technology that benefit a wide variety of applications, please visit www.sparkconnected.com

What's coming next

As wireless power becomes more integral to our mobile and connected lives, Infineon and Spark Connected continue to drive next generation technologies and standards that allow readily available charging without the limitation of wires. What started out with phones will quickly be taken over by applications such as tablets, laptops, handheld gaming, medical devices, automotive, infrastructure and industry 4.0. Given the breadth and different types of wireless power technologies in their arsenal, Infineon and Spark Connected are in a strong position to provide the solutions that allow users to cut that last cord.

In the future, some applications will require very high-power levels or higher frequencies for specific user charging experiences. These applications will benefit from solutions that have improved power/performance capability, such as GaN. In many of these situations, efficiency is the critical metric, and GaN e-mode HEMTs provide a high-power charging solution with a manageable thermal impact. Because of its better high frequency performance, GaN also provides an optimal solution for class E amplifiers in resonant wireless charging.

– Ralf Ködel, Director Product Marketing Management, Automotive & Industrial MicroController Infineon Technologies

– Ken Moore, Chief Executive Officer, Spark Connected

Subscribe to Newsletter

Test Qr code text s ss