Review system inspects mask at EUV level

Article By : Rick Merritt

Inspections of up to 14nm mask defects or a detector supporting 2,000Hz frame rate are just two uphill tests to be at par with EUV wavelength.

« Previously: Manufacturers pick EUV combos

One of the last remaining big pieces of the EUV puzzle is a machine that can inspect masks at EUV wavelength. Carl Zeiss described a prototype system that it has already shipped, although some suggest that a final version may not be available until late 2018.

Carl Zeiss and Samsung described high-resolution systems to inspect masks at the same wavelength as EUV light, where Globalfoundries and Imec both detailed work on 5nm and 7nm nodes using a mix of EUV and current 193nm scanners.

![[samsung EUV (cr)]](/wp-content/uploads/sites/2/2020/04/samsung_EUV_cr.jpg)

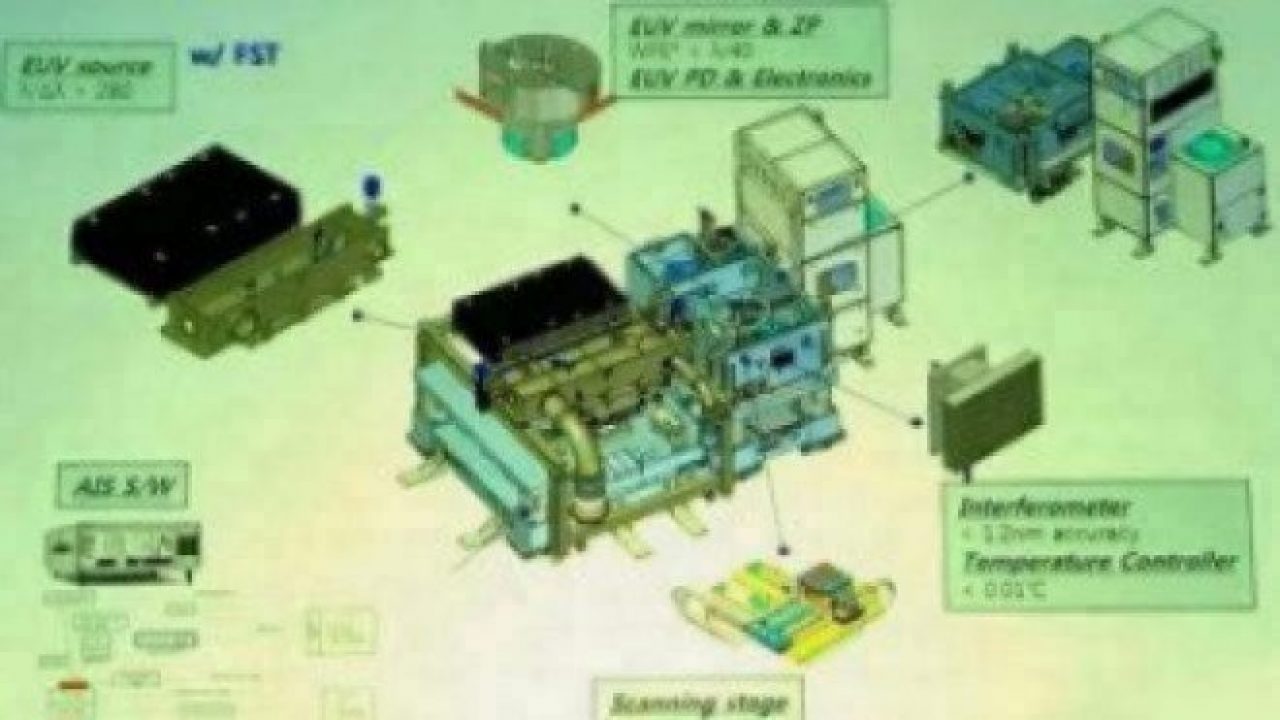

Figure 1: Samsung's EUV mask defect review system or EMDRS.

The Aerial Image Measurement System (AIMS) was tested by a team from Globalfoundries, IBM and Zeiss, who used it to detect 6nm to 14nm defects in masks. AIMS results showed “remarkably good” similarities with wafer-printed results using a 3300B, said Erik Verduijn of Globalfoundries.

Zeiss has four of the systems in development. They can be used to find defects, inspect repairs and create models to predict roughness, said Sascha Perlitz of Ziess.

Two papers described a 5nm/7nm process that Imec developed as an evaluation platform for integrating EUV. The process uses EUV to directly print features with a 32nm metal-2 pitch as an alternative to quad-patterning with today’s steppers.

Imec defined the process using the 3300B system in its Leuven, Belgium, research centre. For the tight overlays needed beyond a 7nm node, engineers would need a 3350 or 3400 system, it said, without referring to throughput issues with the 3300.

![[Samsung emdrs (cr)]](/wp-content/uploads/sites/2/2020/04/Samsung_emdrs_cr.jpg)

Figure 2: Samsung’s EMDRS can detect defects, inspect repairs and find multilayer defects that can’t be seen with less refined systems.

Samsung has been working since 2012 on its own version of a tool. Its EUV Mask Defect Review System (EMDRS) uses a sapphire laser from a Korean supplier known as FST as an EUV light source.

Like the Zeiss tool, Samsung’s EMDRS can detect defects, inspect repairs and find multilayer defects that can’t be seen with less refined systems.

The system is already being used to provide Samsung’s fabs with defect-free masks, said Jihoon Na, a senior engineer in Samsung’s mask group. This year, the team aims to increase its source power and upgrade its optics.

Separately, a researcher from the ETH Zurich institute described core technologies that his group has identified that could be used to create an EUV mask inspection tool. They include the so-called Jungfrau detector that supports a 2,000Hz frame rate, a 106 dynamic range, and modular design. The system’s 5m x 12m Cosami light source is still in the concept stage.

Given the two-year window before any EUV production is expected to start, an enterprising OEM would have just enough of time to ramp up a project. Intel has been calling for such systems for years. For years, KLA-Tencor said that the ROI was too small for such complex systems, but one analyst said that he suspects that the company may be quietly working on one now.

First published by EE Times.

« Previously: Manufacturers pick EUV combos

Subscribe to Newsletter

Test Qr code text s ss