Researchers shrink chemical sensor to fit phone

Article By : Vivek Nanda

Using Raman scattering and a new material, Cornell researchers are close to building a chemical sensor on a chip.

If you need a chemical sensor in the lab, it’s not a problem, according to Jin Suntivich, assistant professor of materials science and engineering. But a chemical sensor that you can takcan e outside with you is a challenge.

Suntivich and other Cornell University researchers are trying to do just that — develop a technology that is small enough to allow personal electronics, yes, like a phone, to constantly monitor the environment around you.

To do that, combining expertise in photonics — manipulating light beams in nanoscale waveguides on a chip – and materials science, Cornell researchers have laid the groundwork for a chemical sensor on a chip.

They are using “Raman scattering” — when a laser strikes a molecule it kicks back the laser energy as photons of light at a variety of wavelengths that depend on the structure and composition of the molecule.

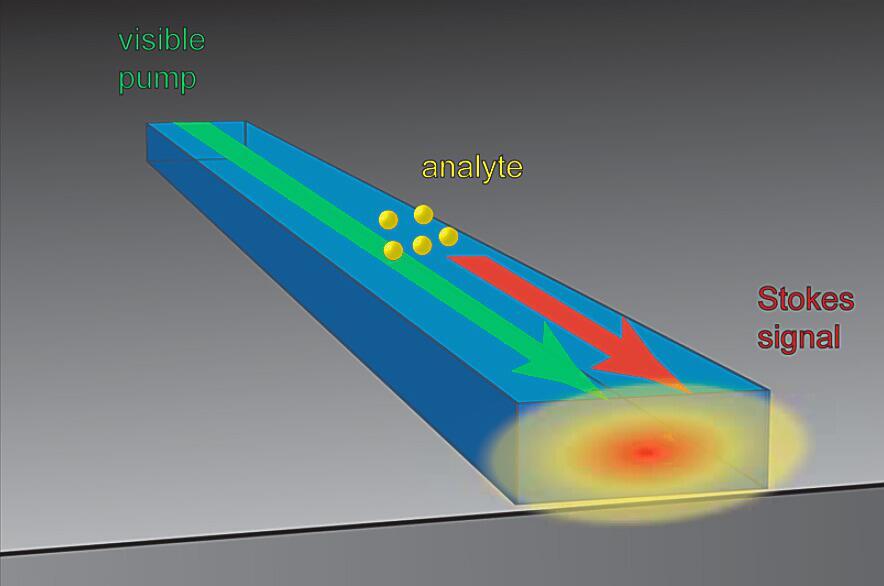

But how do you do that on a chip? The researchers fire a laser into a waveguide — a strip of transparent material made of titanium dioxide, where the light bounces off the inside surfaces and becomes confined to the waveguide. Because a waveguide is only a few nanometres high, the light waves spread out beyond the waveguide, creating a so-called “evanescent field” above the surface of the chip. The pumping laser induces Raman scattering in the space above the chip or in a drop of liquid placed on its surface for analysis, while still confining the light wave to the chip. Light kicked back by the excited molecules also follows the waveguide; a prism at the end of the waveguide can spread that light into a spectrum that is a “fingerprint” identifying the molecule that produced it.

New material

Such sensors have been made before. So what’s new? Sensors previously used silicon nitride waveguides. The Cornell researchers are using a new material — the titanium dioxide — in a design can make a sensor more sensitive and small enough to be used in the field.

Titanium dioxide has a much higher refractive index, making a greater contrast with the space above the chip, which creates a stronger evanescent field. The material is also transparent to light at visible wavelengths, a condition that allows researchers to use a laser at shorter, visible wavelengths, which induce better scattering. The researchers tested with a green laser pointer as a light source.

Interaction of the pumping laser with the material above the chip increases with the length of the waveguide. But the researchers found a way to increase the interaction by using a “ring resonator.” When a circular waveguide is set tangent to a straight guide, some of the light will enter the ring and continue to circle around it, letting the light interact continually with the material above the chip many times. The circumference of the ring can be adjusted to resonate with the wavelength of the light, intensifying the effect.

![[Ring Resonator]](/wp-content/uploads/sites/2/2020/04/RingResonator.jpg)

*__Figure 1:__ A circular waveguide tangent to a straight guide causes light to circulate, giving it more time to interact with material above the chip. The ring is about the diameter of a human hair.*

For a future device, a tiny laser unit can be built into a chip, as can a component that can spread out the wavelengths of the kicked off light onto a photosensitive device to read the spectrum. One possibility is to read the spectrum with the camera in a phone.

Subscribe to Newsletter

Test Qr code text s ss