Is Holography Making a Comeback?

Article By : Junko Yoshida

Holography is coming back — not in the familiar sci-fi movie form of, for example, Princess Leia and R2D2 — but as a commercial head-up display (HUD) for next-generation vehicles to aid drivers and passengers.

ST. ANDREWS, Scotland — Armed with a digital mastering technology, Ceres Holographics, claims that its Holographic Optical Elements (HOE) hold the key to enable car OEMs and Tier Ones to design a HUD dreamed of since the 1980s. The automotive industry has been itching for a transparent display that can display navigation information on the windshield, sparing the driver the distraction of looking away from the road.

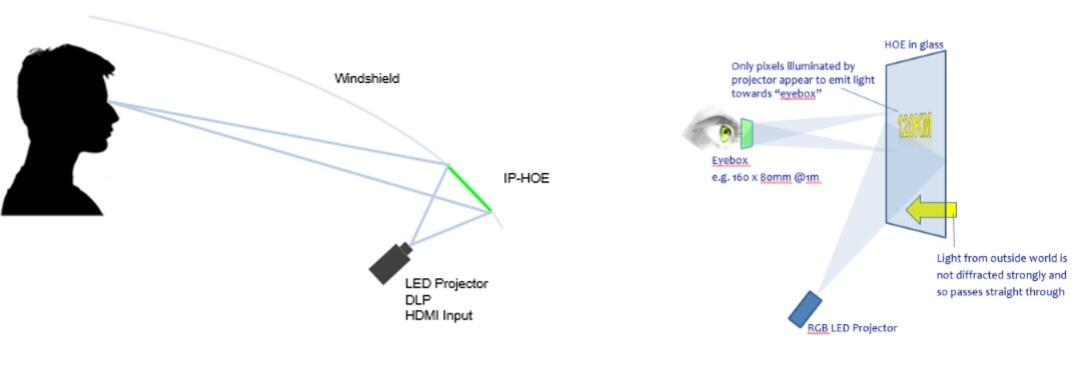

Ceres is confident that its holographic technology can overlay bright, wide field-of-view information onto a curved windshield, using a significantly smaller projector package than anyone has previously been able to develop.

Over the years, carmakers have tried various technologies to generate on-screen images, ranging from CRT and LED to “combiners” using optical waveguides. But none really took off, Ceres CEO Andy Travers told EE Times, “conventional technology needs a projector package that’s too big to fit inside a dashboard.”

Ceres is rolling out its HOE technology in two phases applied to two separate products. First will come a “Transparent Display” (TD) based on a simpler projector. The second will be an “Augmented Reality-HUD” (AR-HUD) with a fancier projector. For both products, Travers told EE Times that Ceres has OEMs and Tier Ones already testing the technology, with some in final testing. Travers envisions the production of cars with TD to start in 2022 or 2023, with cars with AR-HUD to follow a year later.

Briefly…how hologram works

A hologram is essentially a physical recording of an interference pattern created by two beams of light. Ceres CEO Travers described it as “somewhat like photography.”

However, instead of a two-dimensional representation of an object, as captured by conventional photography, a hologram reproduces a three-dimensional light field.

A lens is required in photography to record the image. But this is not so in holographic light manipulation. The light from the object is scattered directly onto a recording medium.

Another important aspect of a hologram, Travers pointed out, is its ability to “actually capture an optical function.” He said, “you can make a hologram of a lens or a mirror, and then basically you could capture that optical function in a very thin piece of holographic film.”

This is what Ceres has done with Holographic Optical Elements. It developed a methodology to capture and digitally master optical functions onto a piece of holographic film.

So, what took them so long?

The technique was invented in 1947 by Dennis Gabor, a Hungarian-British EE and physicist. He won the 1971 Nobel Prize in physics. Many engineers who have grown up reading about holography might be skeptical of claims of success by Ceres, a startup launched in 2009. After all, holography has been around for nearly three-quarters of a century and has yet to find a high-volume application.

Holograms have, however, been used in head-up displays (HUD) for fighter jets, for example, to place a visual frame for targeting weapons systems. The nagging drawback is the use of dichromated gelatin for the materials in HOE, noted Travers. “It’s so toxic that there is no way that material could be used in volume consumer products.”

Setting Ceres apart from competitors in hologram innovation are two factors. First is its years of direct experience in optimizing non-toxic holographic film materials. Second are Ceres’ innovations in digital master printer technology.

Innovations in materials

Let’s start with holographic film materials.

Much of the HOE developed by Ceres takes advantage of new non-toxic photopolymer film materials originally developed by InPhase Technologies, a company spun out of Bell Labs in 2000. InPhase worked on holographic data storage solutions.

InPhase’s photopolymer chemistry was acquired by a German company, Bayer Material Science (now called Covestro), which produced materials called Bayfol HX. The Ceres/Bayfol HX link is Ceres’ founder and CTO Ian Redmond. He worked at InPhase for several years, leading its holographic development effort, where he gained insight into high-performance photopolymer media.

InPhase’ data storage application turned out to be “DOA,” observed Zine Bouhamri, Technology & Market Analyst at Yole Développement, “because competitive technologies came around.”

But the fundamental technologies Redmond learned at InPhase later became foundational knowledge for starting up Ceres when he returned to Scotland from the United States.

Yole’s Bouhamri noted that Ceres “carries a very deep knowledge and understanding of the technology, which helped them develop their products.” More specifically, he said, “their people appear to have been at the beginning of holographic material development for commercial applications. And in an emerging field where technological prowess makes or breaks things, this represents a high advantage.”

Innovation in digital mastering

Beyond holographic film materials, Ceres has distinguished itself by inventing digital master printer technology.

Yole’s Bouhamri said, “We believe [Ceres] are the only one having a digital way of replicating holograms for production, with equipment they build themselves. This likely gives them an advantage over the competition.”

So, what is digital mastering? Ceres’ calls the process “mastering” because it is a little like sound recording. In sound recording, the vibration made by musical instruments or vocal cords is encoded in such a way it can be reproduced later, without the presence of the original vibrating matter. Holography, too, is a technique enabling a light field to be recorded and later reconstructed without the original light field.

In developing digitally controlled mastering, Ceres has optimized its holographic printer around Bayfol HX photopolymer, which Ceres has used, characterized and optimized since 2009.

Ceres’ digital mastering printer can produce a large hologram consisting of numerous 250mm square hologram “pixels.” Travers cautioned that each pixel “is not a TV pixel.” Rather, each one is “programmable,” so that an arbitrary light field can be generated in RGB. Similarly, a reference beam angle is also programmable. Through this mastering process, Ceres can digitally specify and program arbitrary optical functions, such as different types of mirrors and lenses, into a thin flexible film.

With these advances, Yole’s Bouhamri believes that hologram is no longer an elusive technology. He said “a convincing path toward higher volume manufacturing” has been established in the past few years.

Bouhamri singled out “mass manufacturing capabilities” as a major issue for holographic technologies in both AR and HUD. However, due to “long and dedicated efforts from industry veterans in the holographic field,” he expects holographic elements to be designed into a few commercial products soon.

Recommended

EE Times on Air: H is for Hydrogen | And Holograms | And High Performance Computing

Now, Apple is coming into the picture…

Heavy holographic hype returned in 2018, when Apple acquired Akonia Holographics — a company built from the remains of InPhase.

As Yole’s Bouhamri noted, when Apple bought Akonia, “It gave one of the first hints of Apple getting into AR hardware.” That alone was newsworthy. But it also “raised hope for the holographic material use in AR,” he added.

That means by extension that Ceres — whose technology also has InPhase roots — could attract attention from investors and media.

But what about intellectual property? Could Akonia’s and Ceres’ IP possibly cross paths?

Ceres’ Travers explained that Akonia will have all the InPhase-developed data-storage technology, as well as the photopolymer chemistry patents and the right to exploit them. “But I am sure that won’t restrict Bayer/Covestro” [from improving their film materials].

Because Akonia’s business boiled down to making HOE for eyewear, Travers suspects that what Apple acquired was Akonia’s “analog Holographic Optical Elements expertise.” He added, “I am pretty sure that they did not build a digital printer” [like Ceres did], but “they could do that if they had the inclination.”

In other words, Ceres still has all the IP necessary to develop its products without infringing on Akonia/Apple-owned IP. Ceres believes his company’s advantage remains in its digital printer.

Will Ceres have an opportunity to leverage its digital master printer in the development of HOE for AR glasses?

Travers said, “We can digitally master the HOE lens/mirror for eyewear.” In his opinion, digital mastering technology would be superior and more repeatable than analog recording.

Meanwhile, Yole’s Bouhamri counseled caution, because there is no market for consumer AR glasses yet. Apple’s potential entry into AR hardware, nonetheless, is significant at a time when “the big ‘legacy’ players like Microsoft or Magic Leap have been developing and manufacturing a very different technology based on nano-imprint lithography, which we call ‘surface relief gratings.’” Today, there is competition between surface relief gratings and holographic elements, observed Bouhamri. Apple and Ceres are both into holographic elements.

But even in holography, there are options, he noted. “Yole sees the ones going with waveguides (Digilens) and the other ones with simpler reflectors on lenses (Bosch). The industry is expecting waveguides to dominate.”

As for Ceres technology, Bouhamri said, “It could be transferred to AR glasses, but adoption will depend on public response to waveguide versus reflectors. It is not only a question of performance but also a question of cost and… of form factor.”

Challenges ahead

Ceres has already developed a demonstrator system, a DSP-based LED project unit using its own In-plane Holographic Optical Elements.

Ceres’ technologies produce precision HOE in Bayfol photopolymer. Applying its own digital design and mastering technology, the company’s HOE “enables new high-performance transparent displays for automotive and consumer applications,” according to Ceres.

But given that Ceres’ plans to develop TD and AR-HUD in two phases, what does the company foresee as the biggest hurdle that each must clear?

Travers said, “For TD, our major OEM tells that lamination into the windshield remains the only challenge.” However, “For AR-HUD,” he added, “lamination is more difficult and the illumination with respect to temperature-controlled laser diodes is a significant hurdle.”

Asked about challenges Ceres’ HOE-based products might face in the HUD market, Yole’s Bouhamri said, “The challenge will be to provide a solution that provides a high enough field of view, with a good eye box, while not taking up too much volume behind the cluster.” He added, “Yole thinks they have prototypes and demos demonstrating their ability to do that. The other challenge is probably the market in itself, as we know that automotive certifications tend to be long and demanding on many parameters.”

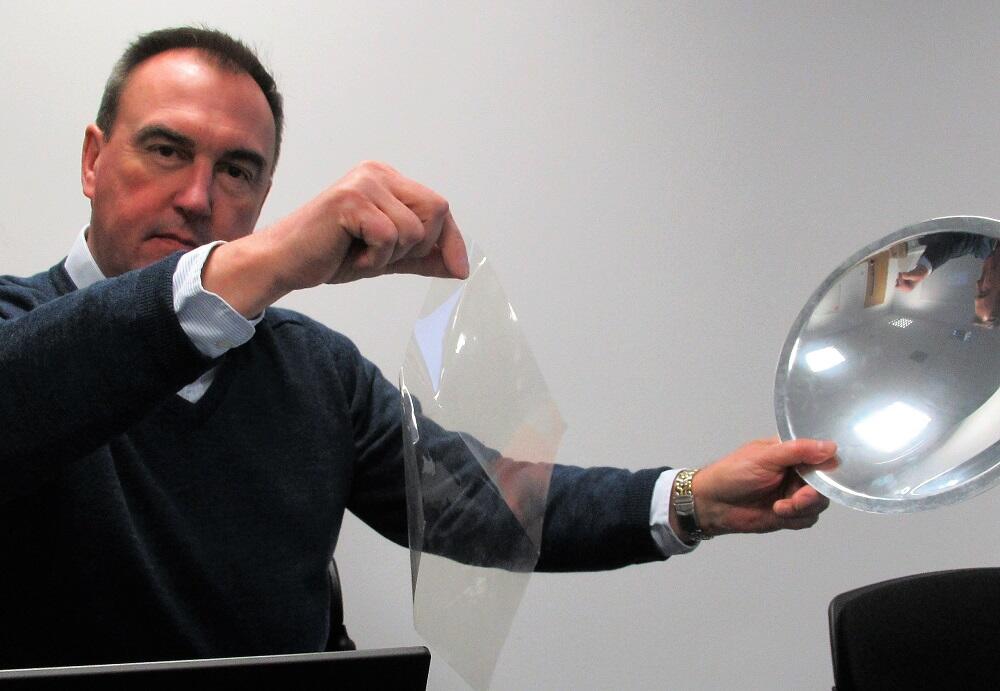

(Image: EE Times)

Why in St. Andrews?

Ceres is tucked away in St. Andrews, a small city with population of 16,800 that almost doubles when the University of St. Andrews is in session.

Ceres currently does not have formal ties with the university. But it’s in the process of building a regional “ecosystem,” said Travers.

Ceres is supporting teams with leading software experts in image correction for HOE-based systems, and technologies enabling real-time content delivery to TD and AR-HUD systems.

Travers explained Ceres’ goal is to build an ecosystem around hologram, which will allow Ceres and partners to “deliver the full stack.” The full stack would include holographic film (from Ceres), projector optics (from projector partners), firmware for basic image correction (from Ceres) and content platform (from Ceres’ partner company). To build momentum for HUD products based on Ceres’ HOE, Travers believes it takes a village.

Luckily, he lives in one.

Subscribe to Newsletter

Test Qr code text s ss