Innovating for a better future

Article By : Industrial Technology Research Institute

ITRI’s ability to incubate new ideas and secure venture investment has recently been recognized by the R&D 100 with two awards for its RAIBA and iKNOBEAD technologies. The R&D 100 is a prestigious award that considers innovation from a global perspective. ITRI has won the award 41 times since 2008.

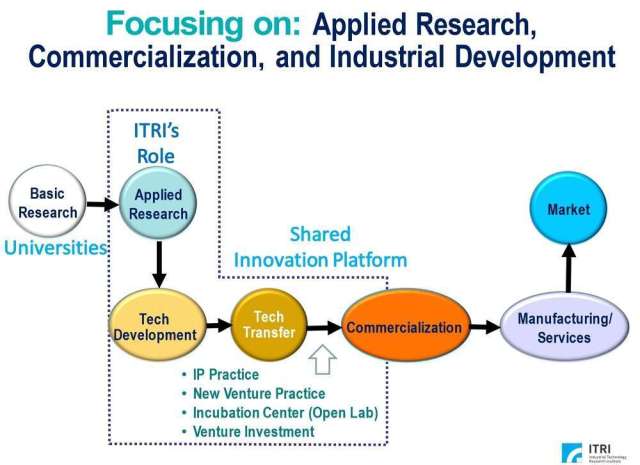

The Industrial Technology Research Institute (ITRI) is dedicated to accelerating the pace of innovation by bridging the gap between university research and commercialization of technology. ITRI drives its own research in addition to supporting innovative companies all around the world.

ITRI’s ability to incubate new ideas and secure venture investment has recently been recognized by the R&D 100 with two awards for its RAIBA and iKNOBEAD technologies. The R&D 100 is a prestigious award that considers innovation from a global perspective. ITRI has won the award 41 times since 2008.

“There is a lot of competition for this award,” said Sean Wang, President of ITRI International, the U.S.-based branch of ITRI. “It is an honor to have our technical team’s effort and innovation recognized on the global stage.”

ITRI helps accelerate development and innovation from early-stage development through the expansion stage to bring technology to market (see Figure 1). To date, ITRI has been awarded over 27,000 patents and created more than 270 spin-offs.

One of ITRI’s key advantages is multidisciplinary convergence. With more than 4,300 engineers (including over 1,000 Ph.D.s), its expertise crosses a diverse range of fields — including electronics, optoelectronics, communications, mechanical, mechatronics, chemical, green energy, environmental, and biomedical, to name a few — enabling an unparalleled level of synergy that drives innovation.

Bringing green power to battery arrays

The first R&D 100 award is for RAIBA — the Reconfigurable and Regulatable Battery Array System. RAIBA technology was created to solve the problem of regulating loads across multiple batteries. When multiple battery units are available to power a system, some batteries may discharge faster than others. This creates inefficiencies that result in an inconsistent current supply, inrush-current issues, and reduced capacity as batteries lose their ability to supply enough current.

RAIBA is implemented as an IC, using hardware and software to control and regulate individual batteries. Each battery unit has a RAIBA IC that connects to a central controller via a standard interface such as SPI. The central controller manages the switch to each battery unit, determining how much current to draw from each unit. For example, the controller can draw more current from a battery with greater capacity to compensate for a battery with lower capacity.

RAIBA can improve efficiency in any system utilizing energy storage, such as electric vehicles, solar installations, and network infrastructure. However, RAIBA provides many benefits beyond efficiency to systems utilizing multiple batteries:

Stability and consistency: By regulating across battery units, RAIBA provides homogeneous discharge. Precise control of the duty cycle for each battery enables RAIBA to accommodate variations in cells and smooth them out.

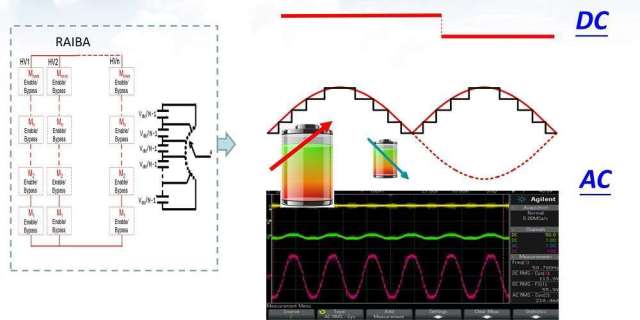

AC/DC output: Because RAIBA controls the duty cycle of each battery unit, the output waveform can be highly controlled as well. This enables a RAIBA controller to output DC or AC from a battery array without requiring an external converter (see Figure 2). This not only results in a more consistent output, it reduces system cost by eliminating converter electronics.

Bidirectional: RAIBA can be used to discharge as well as charge battery units. For example, a solar system would improve efficiency both when charging cells and when they are being drawn from.

Inrush current: Whenever a battery is added to the discharge current, this introduces unwanted inrush current in the output waveform. RAIBA uses a closed loop to control the current drawn from each battery unit and smooth out the waveform, providing continuous, consistent current across the battery array.

Extended battery life: Typically, batteries have to be retired when their capacity drops. With RAIBA, the duty cycle to such batteries can be dynamically adjusted, thus extending the life of such batteries.

Scalable: RAIBA can be scaled without limit to construct battery system for any size.

Major cost savings: RAIBA enables direct in and out to battery units, reducing power conversion losses by ~50%. Because the power control system (PCS) eliminates the need for a conversion circuitry, PCS costs can be reduced by 30%. Precise control of the duty cycle to each battery unit allows energy-storage systems to use retired batteries, reducing costs by 60%. Together, these provide overall cost savings on the order of 35%.

“RAIBA is an important green energy technology,” said Kai-Cheung, division director for ITRI’s Information and Communications Research Laboratories. “The R&D 100 has recognized the impact this technology will have on improving the efficiency of energy-storage systems around the world.”

Conquering cancer

The second R&D 100 award is for ITRI’s iKNOBEAD magnetic bead technology. Its first application is to fight cancer.

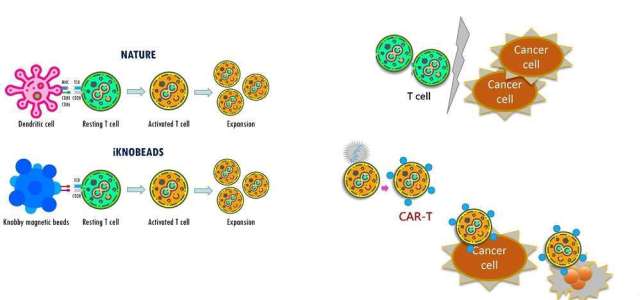

T cells are one of the body’s defenses against cancer. T cells are activated by dendritic cells, which have many arms that can match the surface of T cells to activate them. Once activated, T cells can recognize cancer cells and neutralize them (see Figure 3).

When T cells fail to recognize cancer cells, T cells can be isolated from a patient’s blood and activated externally. Today, activation is accomplished using magnetic beads for CAR-T cell therapy (thereafter referred to as CAR-T beads). CAR-T beads perform the job of dendritic cells by matching the surface of T cells. However, the spherical shape of CAR-T beads limits their surface area and proficiency at activating T cells.

iKNOBEAD technology improves upon existing CAR-T beads by enabling the manufacturing of magnetic beads with an irregular shape. This irregular shape, with many protruding knobs (hence, the name “iKNOBEAD”), more accurately resembles the shape of dendritic cells (see Figure 4). This process is known as biomimicry.

The irregular shape of iKNOBEAD beads results in 2× the effectiveness when activating T cells compared to CAR-T spherical beads. This increase in effectiveness benefits patients in many ways, depending on the individual patient. For example, T cell CAR-T processing takes about 20 days to create an effective density of T cells. With iKNOBEAD technology, a doctor could choose to double the number of activated T cells or provide an equivalent number of T cells in just 10 days at a lower cost. This enables doctors to make trade-offs between T cell density, expense, and speed.

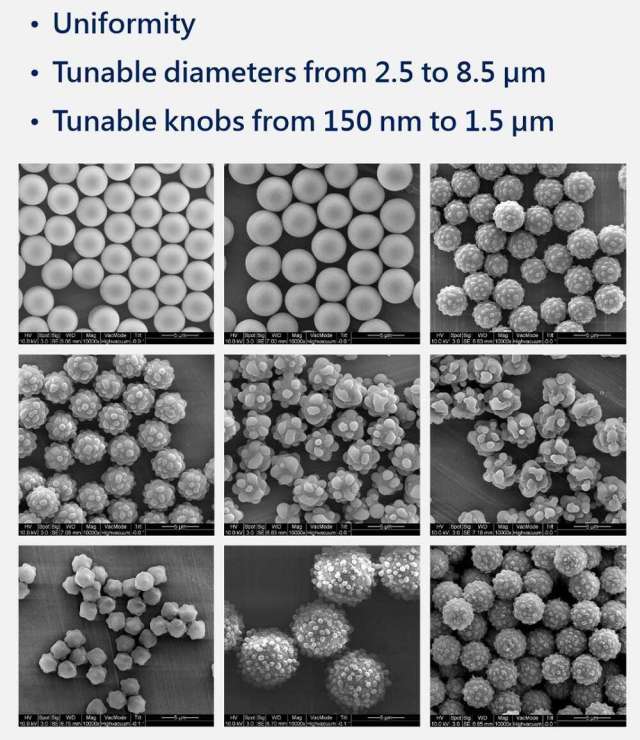

One of the technological barriers that ITRI needed to overcome was developing a manufacturing process that yielded high-quality beads in a repeatable way. The manufacturing process provides a great deal of control to ensure uniformity of beads from lot to lot.

The process also needed to allow variance in bead size and knob size. “One size does not fit all,” said Teddy Chen, manager of ITRI’s Diagnostics and Precision Medicine Technology division. “To address the differing needs of patients, iKNOBEAD technology has a tunable diameter of 2.5 to 8.5 µm, with tunable knobs from 150 nm to 1.5 µm.”

iKNOBEAD technology is proving to be compatible with both types of T cells. Alpha beta T cells, which represent 95% of a body’s T cells, can be used only by the person who created them. Gamma delta T cells, representing the other 5%, can be harvested from healthy donors, activated, and then shared with cancer patients. iKNOBEAD technology is able to amplify the activation of both types of T cells. Thus, the technology will accelerate the impact of T cell therapy and save many more lives.

“ITRI is working to change the world by finding ways to bring innovative technology to market,” said President Wang. “By taking a multidisciplinary convergence approach, we accelerate the evolution of university research into technology that can help people today. ITRI is innovating for a better future.”

With an office in San Jose, ITRI provides North American companies with the technical resources to solve tough technological challenges.

Subscribe to Newsletter

Test Qr code text s ss