Furukawa starts stealth dicing tape production

Article By : Furukawa Electric

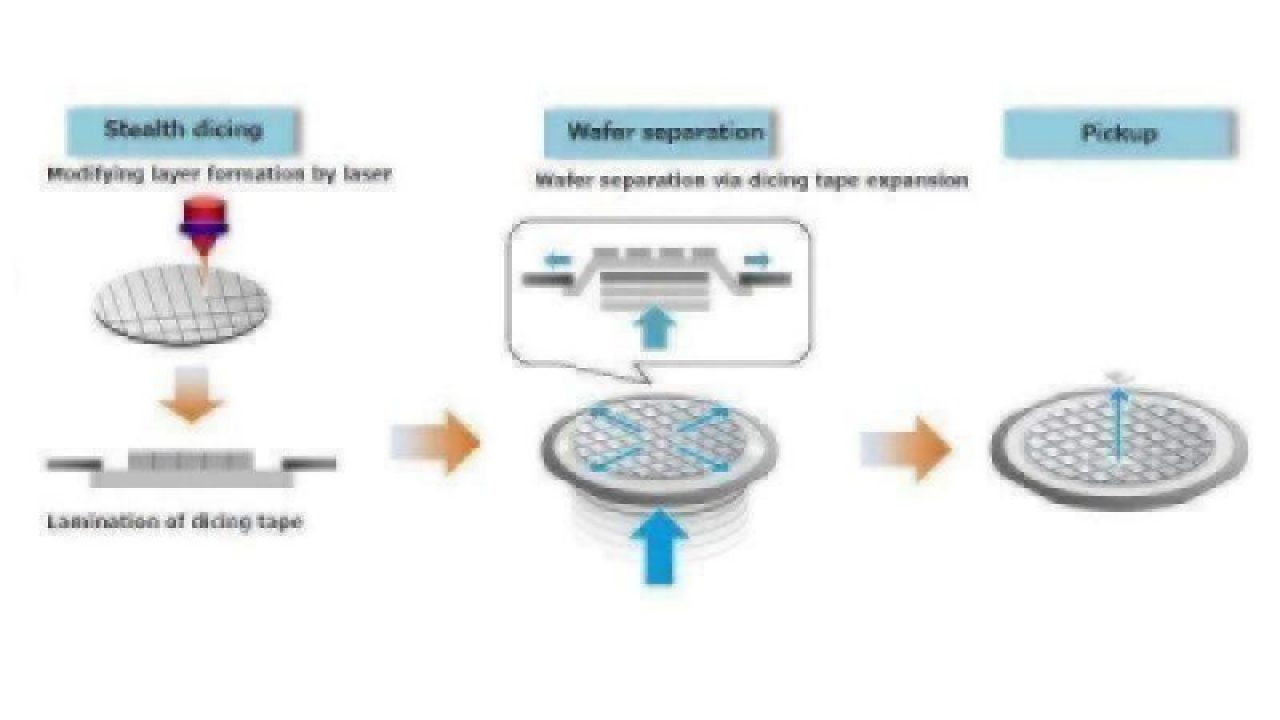

Stealth dicing tape provides uniform expansion of chips without any external stretching, separating the wafers in perfect condition.

Furukawa Electric Co. Ltd. has started mass producing expand separation dicing tape, a tape used with seminconductors to provide high-grade separation of IC chips from wafers after the stealth dicing process.

In conventional manufacturing processes, mechanical methods are used to dice wafers into several IC chips. However, in order to obtain chips with better yields and improved quality, methods in which it is made easier for wafers to be broken into chips (such as using a laser to form a modifying layer inside the wafer) and in which wafers are separated and cut by expanding semiconductor tape applied to wafers in a radial direction are gaining recent attention.

In addition to not breaking even under high speed/high pull expansion conditions subject to heavy loads, expand separation dicing tape offers uniform expansion without any internal stretching or "necking," allowing for wafers to be separated in excellent condition regardless of chip size. The product also offers excellent expansion and preservation characteristics between chips, helping to significantly reduce process machining time. Die attach film (DAF), a crucial component in mounting semiconductor chips, can also be separated and cut along with the chips, resulting in reliable pickup.

The tape comes in a roll with circular DAF attached to the dicing tape. Standard length is 100m/roll; tape thickness varies by type (100 to 200μm).

Subscribe to Newsletter

Test Qr code text s ss