Emerging MEMS Technologies Will Be Built on Paper

Article By : Anne-Françoise Pelé

Emerging MEMS and sensors technologies that will shape the 2020s and 2030s.

No one has a crystal ball to predict the future of MEMS and sensor technologies, but ongoing academic research provides a good indicator of the emerging trends that will shape the next two decades, according to Alissa Fitzgerald, founder of MEMS design & development house A.M. Fitzgerald and Associates LLC. New types of sensor architectures are on their way, as are sensors built on cheap flexible substrates — even paper.

Addressing an audience at SEMI’s MEMS & Sensors Executive Congress last week in San Diego, Fitzgerald said, “Academic research is a fountain of innovations for our industry. Most of today’s blockbuster MEMS products originated from academic research, and we expect that pattern to continue.”

Examples she cited included the SiTime resonator from Stanford University, the CardioMEMS implantable pressure sensor from GeorgiaTech, Vesper’s piezoelectric microphone from the University of Michigan and, more recently, the Chirp piezoelectric micromachined ultrasonic transducers from UC Berkeley and UC Davis.

“My magical method consists in looking at top level academic research from all over the world and filtering through more than 650 papers,” Fitzgerald explained. As for noteworthiness criteria, she said she was looking for “commercial viability, solutions to anticipate problems, and technology game changers.”

Most technologies need many more years of intensive development and probably more than $100 million in investment to reach full commercialization, but what Fitzgerald is sure of is that they each hold potential to create new waves of activity and opportunity in the MEMS and sensor industry.

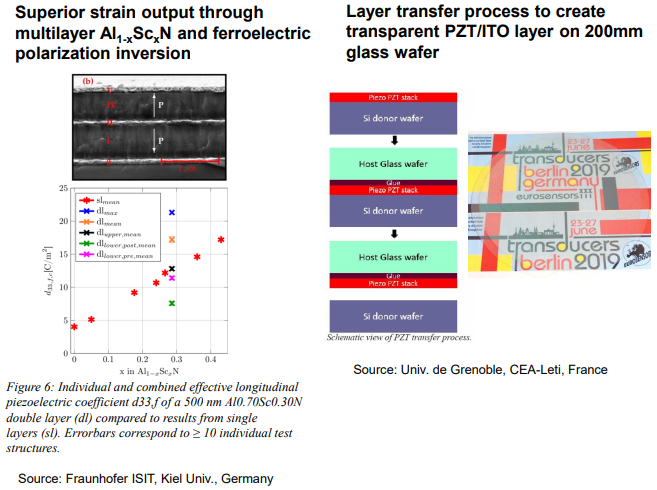

Piezo, piezo, piezo

A change is underway, from the electrostatic comb-drive architecture to thin-film piezoelectric architectures, because “you will be able to get better uniformity of process, more liability, probably higher yields, potentially smaller footprint, and the chip size will be much smaller,” said Fitzergald, citing two recent thin-film material innovations. While the Fraunhofer Institute for Silicon Technology is focusing on multi-layer aluminum nitride, a material with very high piezoelectric coefficient, CEA-Leti has figured out a way to transfer thin-film PZT to a transparent glass substrate and obtain a transparent piezoelectric structure.

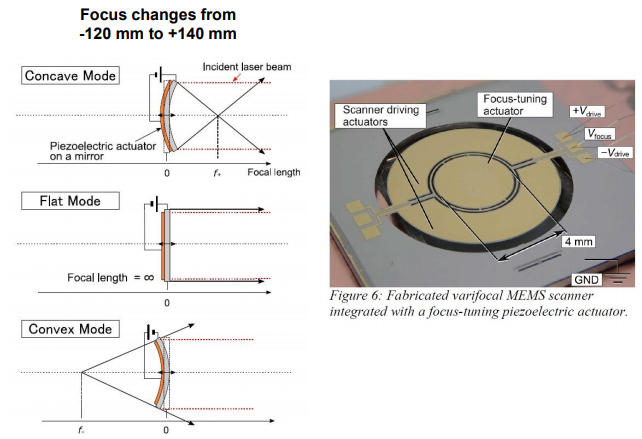

Also interesting are micro-mirrors using thin-film PZT to actuate the mirror. Researchers from the University of Tokyo have designed a 3-axis micro-mirror, though they have only built a 2-axis mechanical structure and controlled the third by using a thin-film PZT to change the curvature of the mirror itself. “They are able to have a very large focal change, and essentially a 3D beam steering,” Fitzgerald said. This technology could be commercialized very quickly.

Thin-film piezoelectric materials will be useful for actuators, speakers, haptics and touch interfaces. “It is easy to call the 2020s as the decade of thin-film piezoelectric MEMS. We already see tons of devices that are using thin-film or aluminum nitride PZT. I think the piezoelectric architecture will displace the electrostatic comb-drive that was strong in the 1990s.”

Today, “the industry is hungry for more robust foundry processes for thin-film piezoelectric and will happily adopt them as soon as they can get them” but, Fitzegerald noted, some work needs to be done to secure reliability and scalability.

Event-driven

“Hey, I just heard the sound you are looking for!” That’s the magic of event-driven sensors. While they wait for a trigger event, they drain zero, or close to zero, power, and their extremely low power consumption eliminates one of the key obstacles to building large sensor-networks: too-frequent battery replacement.

“What I love about these sensors is their clever use of physics, […] you don’t want to be streaming tons of data, and draining power if you are just looking for one event,” Fitzgerald said. These sensors have lots of applications and could be mass-produced very quickly.

Self-powered

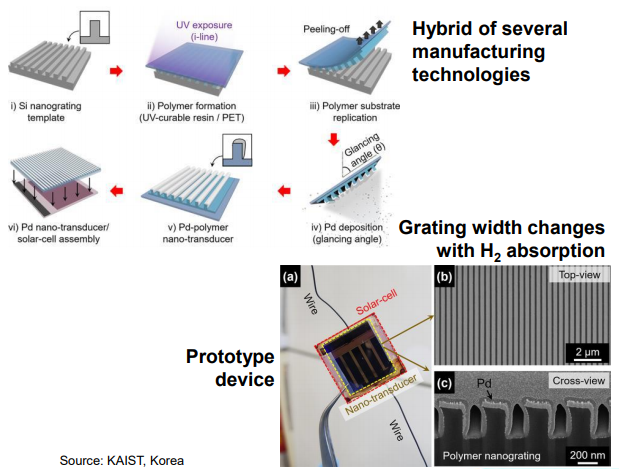

Among more adventurous research, Fitzgerald mentioned the hybridization of a solar cell with a nanoimprint polymer at the Korea Advanced Institute of Science and Technology.

“The presence of hydrogen gas causes the grating of this polymer to swell,” she explained. “With the grating being eliminated onto the solar cell, researchers could measure the current output of the cell and correlate it to the hydrogen concentration. Researchers have developed a totally self-powered cell that will do nothing until it starts detecting hydrogen gas. They envision it for monitoring hydrogen tanks associated with hydrogen-powered vehicles and industrial safety applications.”

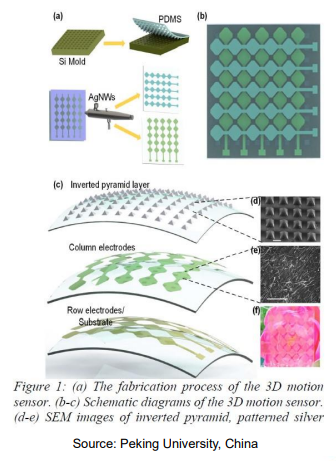

Another example of self-powered sensors comes from the Peking University in China. Researchers developed a self-powered touch sensor that makes use of the triboelectric effect, which is familiar to anyone who has walked across a carpet in their socks and built up a static charge from the friction. Basically, two polymer sheets, with electrodes embedded in them, are pressed together under a touch event, and the sensor can detect pressure and trajectory of the touch motion. This technology, Fitzgerald expects, will have applications for security identification, smart walls, robot touch sensors. It can’t can’t be mass produced yet, however.

Flexible

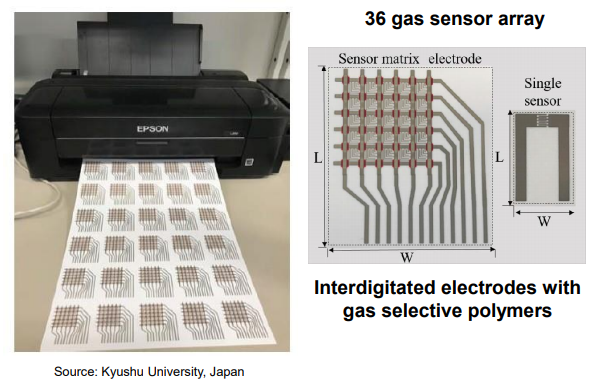

Paper is the ultimate flexible sensor, said Fitzgerald. At the Kyushu University in Japan, researchers are using an inkjet printer to create a 36-gas sensor array that is about the size of a postage stamp. This flexible sensor can measure the gasses released during organic decomposition, which opens the door to a variety of food safety applications. Incorporating such sensors in food packaging materials could, for instance, inform consumers on the freshness of food.

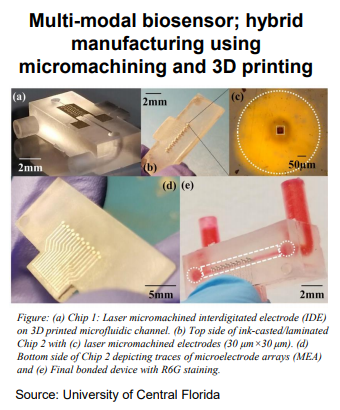

Paper sensors could also be used to detect specific types of bacteria. The University of Central Florida is working on next-generation techniques with 3D printers to create electrical signal-based bacterial detection sensors.

“What’s interesting is that these sensors can not only detect the presence of bacteria,” Fitzgerald said, “but they can tell whether it is e.coli, staphylococcus aureus, or any other types of bacteria.”

These sensors are made on flexible, inexpensive substrate and could be useful for rapid point-of-care diagnostics, not only in developing countries but in every doctor’s office. They could be made as disposable sensors on biodegradable substrates.

Paper, but also plastic and textile MEMS and sensors are set to emerge in the 2030s, said Fitzgerald. One condition, though, is that “we figure out how to mass produce them.”

Micro-manufacturing

Why are we starting to see so much paper, plastic and textile sensor research?” Fitzgerald asked. “A lot of people are frustrated by the lack of access to fab and the lack of access to budget and are very creative about cheap materials they can work with in their not-clean room laboratory.” These materials have the advantage of being readily available, inexpensive and flexible.

The minimal fab is a concept in which each tool is totally self-contained and do not need a clean room environment. “This is a viable manufacturing path for a lot of customers who are focused on low-volume precision sensors and only need a thousand sensors per year.” She continued: “There are plenty of high performance applications where going to a mega-foundry is not even possible because you need one wafer per year, and no foundry would take that business.”

Similarly, 3D printers are starting to be efficient. They can now print layers in resolution of several tens of microns and print plastic, metal and ceramic materials. Today, people hybridize more and more 3D printing with silicon nanoimprint lithography. This can lead to new types of sensors.

According to Fitzgerald, “We are going to continue to see this hybridization of semiconductor manufacturing with low cost methods. And, once we have manufacturing on 3D printers, this can happen in people’s garages.”

Today’s manufacturing infrastructure is slowing progress. Researchers use inkjet printers, 3D printers to manufacture prototype sensors, but they too often need to adopt roll-to-roll printing to scale up. If a solution is not found, it may take a decade to see paper, plastic and fabric sensors reach mass production. In a call-to-action, Fitzgerald said “we should think collectively at how to evolve sensor manufacturing infrastructures.

“For those of us, who are in the silicon manufacturing business, we should be thinking about how to add new flexible substrate technologies as a plus, an addition, not an instead-of. And, once we have figured out how to scale these technologies, I think some exciting things are going to happen,” Fitzgerald concluded.

Subscribe to Newsletter

Test Qr code text s ss