Can a 3D printer co-robot make ‘mass customisation’ easier?

Article By : R. Colin Johnson

The co-robot revolution comes along just in time for Tend.ai's purposes, since co-robots can now work alongside humans without the risk of harming them.

An artificially intelligent robot wants to help entrepreneurs set up their own factory in minutes, even if they don’t have the technical knowledge yet.

Tend.ai claims to be the world's first artificially intelligent (AI) cooperative robot (co-robotic) tender of 3D printers, in-circuit-testers (ICTs) for printed circuit boards (PCBs), punch presses and other automated manufacturing devices.

Using a web cam attached to the robot's gripper and thin-client into which the user plugs all their devices, its AI software in the cloud manages the performance of all the tasks workers would have to perform manually. This includes configuring all devices, pushing their buttons, moving partly constructed devices from machine to machine, fetching the final manufactured parts and packaging them into boxes.

The Tend.ai video demonstrates all the steps necessary to set up your own factory in minutes to take advantage of the "mass customisation" manufacturing revolution brewing in the United States.

"Evidence shows that bringing manufacturing back to your own country can be accomplished by making fully automated factories," Mark Silliman, CEO of Bold Robotics LLC (Bend, Ore., doing business as Tend.ai) told EE Times in an exclusive interview "The transfer from 'mass production' to 'mass customisation' is the driving force plus the ability of local factories to deliver two-day turn-around instead of shipping all the way from China."

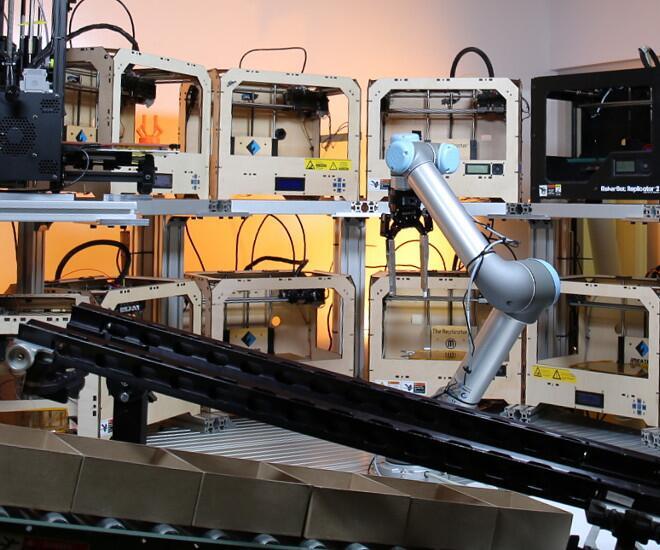

![[co-robot 01]](/wp-content/uploads/sites/2/2020/04/EETA_co-robot_01.jpg)

__Figure 1:__ *Tend.ai software controls a single co-robot arm centrally located so it can move partially manufactured products from automated machine to machine until finished when it puts the product into a box (foreground) for two-day turnaround shipping to the customer. (Source: Tend.ai)*

Serial start-up founder, Silliman, got the idea from a fellow entrepreneur who was manufacturing custom cookie cutters out of her garage, where he observed her continually running back-and-forth to remove finished parts from her 3D printer and set up the next job manually. From there Silliman—who has financed Tend.ai with angel funding—discovered that not only 3D printers doing additive manufacturing, but traditional subtractive manufacturers using CNC, punch presses, cutters and ICTs for PCBs were in need of robotic tenders to fully automate U.S. manufacturing.

The co-robot revolution came along just in time for Tend.ai's purposes, since co-robots can now work alongside humans without the risk of harming them.

"Traditional robot arms have to be caged when working around humans to prevent them from harm, but co-robots have changed the manufacturing landscape," Silliman told EE Times. "In fact, last year there were just three co-robot makers, but today there are at least seven."

The editor/publisher of The Robot Report, Frank Tobe, confirmed Sillman's claim that co-robots are flourishing, at least in terms of how many start-ups are coming on board.

![[co-robot 02]](/wp-content/uploads/sites/2/2020/04/EETA_co-robot_02.jpg)

__Figure 2:__ *Using an iPad, the user tells Tend.ai’s software each step the co-robot is to perform during manufacturing, here highlighting the significant part of the 3-D printer’s display that the Tend.ai’s neural network should learn to recognise. (Source: Tend.ai)*

"Universal Robots and Rethink Robotics are the two pioneers in collaborative robotics, but they were closely followed by Kuka’s lightweight LBR iiwa co-robot and their soon-to-be-released Roberta arm," Tobe told EE Times in an exclusive interview. "Other vendors of co-robots include ABB’s YuMi, a two-armed robot; pi4’s Workerbot3 [which was a big hit at the recent Automatica trade fair in Munich]; the slick new low-cost Franka arm, which won awards and drew big crowds at this year’s Hannover Messe [Germany]; MABI Robotic’s arm, Smokie Robotics OUR-1 and OUR-2 co-robots; and F&P Robotics, with its lightweight arm, are all producing and selling co-robots right now. Many other companies at Automatica said they were developing co-robots now, but would launch them sometime next year."

![[co-robot 03]](/wp-content/uploads/sites/2/2020/04/EETA_co-robot_03.jpg)

__Figure 3:__ *The co-robot arm manages the automated machines just as a human worker would, here pushing the ‘go’ button after setting up the 3D printer. (Source: Tend.ai)*

Tend.ai claims to be the first company to provide turn-key software to integrate co-robots with automated manufacturing tools. Tend.ai is 3D printer, ICT, CNC, punch press and cutter agnostic, setting up its software for use with any manufacturing configuration. The webcam (attached to the gripper and a small thin-client into which all devices are plugged) is supplied to Tend.ai users, but all the real work is done by its cloud-based software. To set up, the user has no programming to perform, but merely drags its robotic-arm gripper through the motions it is expected to perform—including pushing buttons—during which Tend.ai's neural network in the cloud learns the necessary operations from the web cam's video data stream and the robotic arm's position encoders which communicate its gripper's location and orientation.

![[co-robot 04]](/wp-content/uploads/sites/2/2020/04/EETA_co-robot_04.jpg)

__Figure 4:__ *After manufacturing the co-robot arm is here preparing to pick up the finished part and put it in a box for shipping.*

The user only needs a tablet to run Tend.ai's cloud-communication software; the neural network in the cloud does the rest. The cloud software also correlates its newest learning algorithms with those it has already learned from other users. Consequently Tend.ai routinely upgrades the software for all its users with similar configurations whenever its neural network learns a more efficient way to perform a common task. The users themselves need no technical knowledge to set up and operate Tend.ai. Manufacturers are charged only for the computer time its cloud-based software logs each month—using the software-as-a-service (SaaS) model.

Tend.ai is still growing its customer base, from the grass roots up, but it claims to be working with hundreds of companies in automating manufacturing in areas ranging from agricultural to aerospace to medicine.

Subscribe to Newsletter

Test Qr code text s ss