Wide bandgap semiconductor switches optimization for EMI compliance

Article By : Rohde & Schwarz

Correlated time-frequency measurements optimizes gate driving and minimize EMI emission

The

wide bandgap materials such as silicon carbide (SiC) and gallium nitride (GaN)

for semiconductor switches are able to operate at high switching frequencies

with steep rising edges and high voltage. These characteristics enhance the

efficiency of switching power supplies but at the same time increase the

challenges for EMI compliance. Optimizing for EMI compliance during development

phase would reduce effort needs at later stage.

One

source of EMI emission is the fast switching MOSFET bridge. A direct approach

to reduce EMI is to modify the gate driving voltage of the switching

transistors. This requires parallel measurement of the gate driving voltage,

the output signal and the emitted radiation, as well as their spectrum.

|

|

|

|

(a) |

(b) |

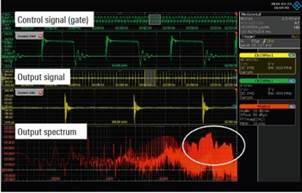

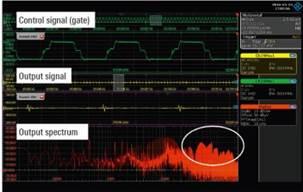

Figure

1: Various drive signals of MOSFET bridge and their effect on emitted

radiation. © IFE Graz University of Technology Austria

In

Figure 1, the EMI emission of MOSFET bridge (red) is significantly reduced by

optimizing the gate driving voltage (green). Observing the green waveforms,

1(a) uses a rectangular gate drive signal while 1(b) uses a cascaded two-level

gate drive signal. EMI emission is observed in parallel with a near field

probe. It clearly shows the amplitude of high frequency components in EMI signal

(red) is reduced effectively.

The

test solution

Rohde

& Schwarz oscilloscopes have direct frequency and resolution bandwidth

input and fast update rate. Combining with the R&S®HZ-15 compact probe set

for E and H near-field measurements and R&S®HZ-17 compact H near field

probe set (both 3GHz bandwidth), the source and transmission path of unwanted

emissions on a PCB can be easily located.

To

learn more on this EMI emission test and further optimization steps, click here.

Explore

also: From

the industry experts to you: detect EMC issues early!

Subscribe to Newsletter

Test Qr code text s ss