Imec and ASML Join Forces on Post-3nm Processes

Article By : Nitin Dahad, EE Times

Five year program aimed at creating next-gen nanoscale devices

LONDON — Research organization Imec and lithography equipment manufacturer ASML plan to establish a joint research lab to explore printing nanoscale devices towards the post-3nm logic node.

The collaboration is part of a new five-year program that builds on a near 30-year relationship between imec and ASML and will have two phases. The first is to develop and accelerate the adoption of EUV lithography for high-volume production, including the latest available equipment for EUV.

The second phase will explore the potential of next-generation high-NA (numerical aperture) EUV lithography to enable printing of even smaller nanoscale devices advancing semiconductor scaling beyond 3nm.

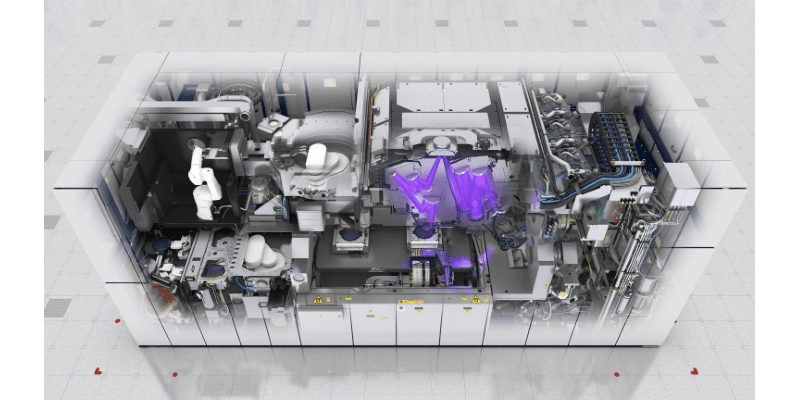

As part of the first phase, the new lab will install ASML’s NXE:3400B high-volume production dedicated EUV scanner in Imec’s cleanroom by the end of this year and will look to evolve and improve the current 0.33 NA EUV lithography technology. Utilizing Imec’s infrastructure and technology platforms, imec and ASML researchers and partner companies will use the lab to proactively analyze and solve technical challenges such as defects, reliability and yield, and accelerate the industrialization of EUV technology.

The NXE:3400B EUV system, with its 250W light source, provides a throughput of more than 125 wafers per hour, an important requirement for high-volume production. The system installed at Imec will also be equipped with the latest alignment and leveling sensors to enable optimal process control at this high throughput to facilitate overlay matching to that of the latest immersion scanner, NXT:2000i, which will be installed in imec’s cleanroom in 2019.

In addition, ASML and Imec will expand the metrology capability with new ASML YieldStar optical metrology and ASML-HMI multi-electron beam metrology equipment, allowing more accurate and faster evaluation of nanoscale structures.

As part of the second phase, Imec and ASML will establish a joint high-NA EUV research lab, in which researchers from both organizations will experiment with next generation EUV lithography at higher NA. Systems with a higher NA project the EUV light onto the wafer under larger angles, improving resolution, and enabling printing of smaller features. More specifically, the new high-NA EUV EXE:5000 system that will be installed in the joint research lab will have an NA of 0.55 instead of 0.33 in current NXE:3400 EUV systems.

The TWINSCAN NXE:3400B will support EUV volume production at the 7 and 5 nm nodes. Source: ASML.

ASML bills the EXE:5000, which will be ready by 2021, as its new next generation EUV lithography platform. The high-NA system will enable geometric chip scaling beyond the next decade, offering a resolution and overlay capability which is 70% better than ASML’s current EUV systems, according to the company.

Luc Van den hove

Luc Van den hove, president and CEO of Imec, told EETimes that the first of these new machines will come into the joint high-NA EUV research lab for early testing. Asked about the challenges that Imec foresees in developing systems to print at 3nm, Van den hove said that the three key tracks of research the research institute will be working on are photoresist technology, pellicle technology and process optimization of illuminators and scanner settings.

“Photoresist technology will need further improvements to reduce defectivity,” Van den hove said. You want photoresist that is sensitive but then higher sensitivity increases defectivity.”

He said it’s a very iterative process, which can gradually improve performance, but it has been quite slow to evolve over the years. However, with more EUV systems being deployed, there are more resist suppliers in the ecosystem, which in turn can lead to more opportunities for improvement at a faster pace, he said.

Pellicles for EUV have been slow in coming. Van den hove said the big challenge remains transparency, which Imec plans to address. Van den hove added that a key part of Imec’s role in the development of current EUV technology is the ability of the organization to align all the players — from the resist and mask suppliers to the inspection and metrology as well as end-customers — to prepare for its introduction.

Subscribe to Newsletter

Test Qr code text s ss