Semiconductors: China Goes Its Own Way

Article By : Alan Patterson

Outcast from the recent mergers & acquisitions frenzy, China develops its own infrastructure

TAIPEI — Uninvited to the recent M&A party for the global semiconductor industry, China has been instead looking to build its own bustling ecosystem, a complete domestic supply chain including design, manufacturing, materials, and equipment.

The nation is betting it may have a market big enough to do everything on its own. China appears undaunted in its efforts to become a key chipmaking nation. Even so, the gap between the nation’s semiconductor imports and exports continues to widen. Despite the rapid growth of China’s domestic semiconductor industry, the nation imported $260 billion in chips but exported only $67 billion in 2017, ballooning imports to $193 billion from $166 billion in 2016.

Credit Suisse Vice President Randy Abrams noted in a report on the March 14-16 China Semicon show that the domestic industry is gaining some traction.

“We walked away with a sense that China is deeply committed to its semiconductor development initiatives, and lack of IP or M&A will not stop it from investing,” Abrams said in the report. “There are new entrants emerging in every part of the semi supply chain.”

Many presentations at Semicon China focused on collaboration within the China ecosystem and the broader global community to try to create a high-growth market. Credit Suisse expects China to pursue acquisitions against political pressure that increasingly will keep the nation out of large-scale global M&A or IP acquisitions, forcing China to set its targets on smaller companies or lower-profile joint ventures.

Speaking at Semicon China, Mentor CEO Walden Rhines refuted the notion of a consolidating chip industry, commenting instead that new companies in China are reshaping the landscape. Other top executives of multinational companies in the semiconductor supply chain speaking at the event said that the many fabs that China is building nationwide present a huge business opportunity.

China has allocated 86 percent of the total funds in its first national IC fund at 138 billion yuan ($21.9 billion), and is in the process of raising a second fund that Credit Suisse expects to be larger than the first at about 150 billion yuan. China remains committed to import substitution by building local suppliers and encouraging international companies to localize manufacturing in China and form joint ventures with local partners.

New Memory Fabs Ramping

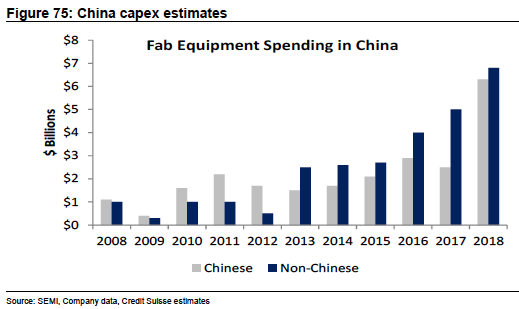

While China lacks intellectual property, government-backed companies are proceeding with three new memory fabs that are ramping this year. The companies were a focus of discussions at the Semicon show. Fujian Jinhua Integrated Circuit Co. (JHICC) and Innotron Memory are starting DRAM production, while Yangtze Memory Technologies Co. (YMTC) plans to launch 3D NAND products. Those companies are part of a nationwide building binge. Industry organization SEMI estimates that China’s capital expenditure on fab equipment will increase from $7.6 billion in 2017 to $13 billion in 2018, making China the second largest buyer globally.

In memory, China’s key projects include YMTC, which will work with China’s government backed Tsinghua Unigroup in NAND and DRAM projects. Innotron and the Fujian government’s JHICC will start DRAM production in the second half of this year.

YMTC has been sampling 32-layer NAND flash and JHICC and Innotron have been developing 22nm DRAM.

The Chinese companies see business opportunities as the hugely profitable memory is likely to remain that way for some time to come. The business is expected to stay healthy during 2018, with controlled supply growth and data center demand offsetting the weaker mobile business, according to Credit Suisse.

JHICC appears to improving yields based on Credit Suisse’s conversations with equipment suppliers. JHICC is sampling DRAM products at 22nm, similar to Micron’s 20nm process.

The Chinese DRAM startup is expected to ramp 10,000 to 20,000 wafer starts per month (WSPM) of capacity in the third quarter this year. That figure would put JIHCC at about 1.5% of global wafer starts.

The company is starting production at the same time as it faces a legal battle. There is ongoing litigation regarding intellectual property between JHICC and Micron. The Chinese company developed DRAM chips with Taiwanese partner United Microelectronics Corp. (UMC). UMC and Micron have countersued each other over memory-related IP. Even so, the legal kerfuffle may not amount to much.

“Most people we talked to in China do not believe that IP would be a sufficient barrier to stop China from entering memory,” Credit Suisse’s Abrams said in his report. He noted that in a recent legal case between Veeco Instruments of the U.S. and Advanced Micro-Fabrication Equipment Inc. (AMEC) of China, the Chinese courts decided in favor of AMEC.

Technical Challenges

The Chinese companies face technical challenges as well. YMTC’s yields are still very low on NAND, according to Credit Suisse. The Chinese company has been sampling 32 layer NAND since the end of 2017, but yields are still very low at about 10 percent, the investment bank said. YMTC is expected to ramp capacity to 20-30k WSPM by end of this year.

Innotron, a company that has no website under its own name, is expected to start volume production by this year and reach 20k wafers per month by the end of 2018.

DRAM pricing is still projected to rise about 3 percent quarter on quarter in the second and third quarters this year, and NAND pricing is falling less than feared in the first half this year. Prices dropped 3-5 percent during the first quarter, 10 percent in the second quarter and are expected to stabilize during the second half this year. The memory industry remains in a good supply-demand balance as storage requirements continue to grow in the data center, according to Credit Suisse.

The memory market increased 75-80 percent in 2017, despite a 47 percent increase in average selling prices, according to memory market watcher DRAMexchange in Taipei. In 2018, the company is forecasting 30-35 percent sales growth while ASPs rise 10 percent.

Memory is the second largest device type where the gap between domestic production and demand is widening in China. The nation accounts for 12 percent of the world’s memory production, primarily from multinationals in China such as Samsung, Hynix and Intel. With the gap between China’s memory imports and domestic memory production still widening, there may be room for China’s three new memory makers to grow.

— Alan Patterson covers the semiconductor industry for EE Times. He is based in Taiwan.

Subscribe to Newsletter

Test Qr code text s ss